9. Procedure

9.1 Sample Preparation - Mix the whole sample, as received, thoroughly using a high speed mixer when practicable, for 30 s. In all cases a sample taken on a glass or PTFE rod dipped to the bottom of the container must show a homogeneous appearance. For fuels with a high wax content (high pour point), or of very high viscosity, the sample must be heated before stirring. The temperature must be either 15°C above the pour point in the case of low viscosity fuels, or that equivalent to 150 to 250 cSt in the case of high viscosity fuels. In no case should the temperature exceed 80°C.

9.2 Filter Preparation - For each test, dry two filter media for 20 min in the oven at 110°C. Transfer each paper, separately, rapidly to a numbered weighing bottle and allow to cool in the cooling vessel to room temperature (5 to 10 min). Weigh each weighing bottle plus filter medium to the nearest 0.0001 g.

NOTE 1 - The Whatman GF/A filter media are fragile and are to be handled with care. Before use, check each medium for consistency, and the possible presence of small defects (holes).

NOTE 2 - For convenience, it is useful to have a number of weighing bottles dedicated to the procedure, the lightest of which is chosen as the tare. All weighing bottles should be stored in a desiccator in the vicinity of the balance. Do not place these weighing bottles in the oven since their weights are in equilibrium with the desiccant.

9.3 Apparatus Assembly - Before use, check that the filter support screen is clean. If necessary, the screen must be cleaned by boiling in a high boiling point aromatic solvent. When more than 2 % of the sinter area remains blocked by particulate matter after such cleaning, discard the screen and install a new one.

9.3.1 The filtration unit must be clean and dry before assembly. Stack the two previously dried and weighed filter media on top of the sinter support with the mesh imprint side down, using forceps, placing the one from the lower numbered weighing bottle on the bottom. Apply slight vacuum to aid in centering the filter media, and place the top portion of the filtration apparatus carefully on to the media before clamping. Shut off the vacuum and pass steam at 100 more or less 1°C through the heating/cooling coils for 10 min prior to sample addition.

9.4 Sample Addition - Into a 30 mL beaker, pour approximately 11 g of the fuel sample prepared as described in 9.1 and weigh to the nearest 0.01 g. Connect the vacuum source and apply vacuum to an absolute pressure of 40 more or less 2 kPa minimum (61.3 kPa vacuum). Heat the contents of the beaker to 100 more or less 2°C. Then transfer the contents at 100 more or less 2°C (Note 3) to the center of the filter medium, taking care that no sample touches the walls during transfer (Note 4). Reweigh the beaker to the nearest 0.01 g. The quantity transferred should be 10 more or less 0.5 g. When filtration is not complete in 25 min, discontinue the test and repeat using 5 more or less 0.3 g of sample. If filtration is still not complete in 25 min, report the result as filtration exceeds 25 min.

NOTE 3 - It is expedient to weigh the beaker plus stirrer plus temperature measurement device before and after transfer to avoid errors incurred by attempting to obtain a net weight. Any convenient means of heating the fuel sample to 100 more or less 2°C may be used, such as hot plate, water or oil bath, or an oven when equipped with a suitable stirrer. Samples that overheat above 105°C must be discarded and not reused.

NOTE 4 - For samples of high viscosity or high sediment, level filtration will be aided by small stage or even dropwise addition. It is preferable to avoid complete coverage of the filter medium with unfiltered oil sample. For samples of low filtration rate the pressure of 40 more or less 2 kPa should be maintained for the 25-min period.

9.5 Filter Washing - When the filtration is complete and the upper filter medium appears dry, continue the steam and vacuum for a further 5 min. Discontinue the steam supply and cool the apparatus by passing tap water through the coils. Wash the filtration unit carefully with two portions of 25 more or less 1 mL of the wash solvent from a syringe or graduated wash bottle with a fine nozzle, taking care to remove any adhered sample from the wall of the upper part of the apparatus. Carefully remove the top portion of the filtration unit and wash the rim of the filter with a further 10 more or less 0.5 mL of the wash solvent in a similar manner. Finally wash the whole of the filter medium area with 10 more or less 0.5 mL of n-heptane.

NOTE 5 - If the sample filters very rapidly, the vacuum should be released before the first solvent washing, to ensure complete coverage of the filter medium area by solvent. The vacuum should then be gently reapplied for the subsequent operations.

9.6 Apparatus Disassembly - After the filter medium appears dry, discontinue the vacuum supply. Using the forceps, carefully remove each filter medium separately and transfer them to the oven at 110°C. Dry for 20 min and quickly transfer them to the same numbered weighing bottles as used in 9.2. Allow them to cool in the cooling vessel (6.14) to room temperature (5 to 10 min) and reweigh them to the nearest 0.0001 g.

10. Calculation

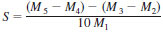

10.1 Calculate M2, M3, M4, and M5 by subtracting the masses recorded in 9.2 and 9.6 with the mass of the corresponding weighing bottle. For each test specimen with a calculated total sediment concentration >0.005 % m/m as determined by Eq 1, record the mass percentage of total sediment to the nearest 0.01 % m/m. For each test specimen with a total sediment concentration #0.005 % m/m, record the result as 0.00 % m/m.

where:

S = total sediment, % m/m,

M1 = mass of sample, g,

M2 = mass of lower filter medium before filtration, mg,

M3 = mass of lower filter medium after filtration, mg,

M4 = mass of upper filter medium before filtration, mg, and

M5 = mass of upper filter medium after filtration, mg.