ASTM D4815 Standard Test Method for Determination of MTBE, ETBE, TAME, DIPE, tertiary-Amyl Alcohol and C1 to C4 Alcohols in Gasoline by Gas Chromatography

12. Calibration and Standardization

12.1 Identification - Determine the retention time of each component either by injecting small amounts separately, in known mixtures, or by comparing the relative retention times with those in Table 1.

12.1.1 To ensure minimum interference from hydrocarbons, it is strongly recommended that a fuel devoid of oxygenates be chromatographed to determine the level of any hydrocarbon interference.

12.2 Preparation of Calibration Samples - Prepare multi-component calibration standards of the oxygenates and concentration ranges of interest, by mass, in accordance with Test Method D4307.

12.2.1 For each oxygenate, prepare a minimum of five calibration standards spanning the range of the oxygenate in the samples. As an example, for full range calibration, 0.1, 0.5, 2, 5, 10, 15, and 20 mass % of each oxygenate may be used.

12.2.2 Before preparing the standards, determine the purity of the oxygenate stocks and make corrections for the impurities found. Whenever possible, use stocks of at least 99.9 % purity. Correct the purity of the components for water content, determined by Test Method D1744.

12.2.3 To minimize evaporation of light components, chill all chemicals and gasoline used to prepare standards.

12.2.4 Prepare standards by transferring a fixed volume of oxygenates, using pipettes or eye droppers (for volumes below 1 volume %), to 100-mL volumetric flasks or septum capped vials as follows. Cap and record the tare weight of the volumetric flask or vial to 0.1 mg. Remove the cap and carefully add the oxygenate to the flask or vial. Do not contaminate with sample the part within the flask or vial that contacts the cap. Cap and record the net mass (Wi) to 0.1 mg of the oxygenate added. Repeat the addition and weighing procedure for each oxygenate of interest. Similarly, add 5 mL of the internal standard (DME) and record its net mass (Ws) to 0.1 mg.

12.2.5 Dilute each standard to 100.0 mL with oxygenate-free gasoline or a mixture of hydrocarbons, such as isooctane/mixed xylenes (63.35 volume %). Do not exceed 30 volume % for all oxygenates, including the internal standard added. Store the capped calibrations standards below 5°C (40°F) when not in use.

12.3 Standardization:

12.3.1 Run the calibration standards and establish the calibration curve for each oxygenate. Plot the response ratio (rspi):

rspi = (Ai/As)

where:

Ai = area of oxygenate, and

As = area of internal standard.

as the y-axis versus the amount ratio (amti):

amti = (Wi/Ws)

where:

Wi = mass of oxygenate, and

Ws = mass of internal standard.

as the x-axis calibration curves for each oxygenate. Check the correlation r2 value for each oxygenate calibration. The r2 value should be at least 0.99 or better. r2 is calculated as follows:

where:

and:

Xi = amti ratio data point,

X = average values for all (amti) data points,

Yi = corresponding rspi ratio data point, and

y = average values for all (rspi) data points.

12.3.2 Table 3 gives an example on the calculation of r2 for an ideal data set Xi and Yi:

12.3.3 For each oxygenate i calibration data set, obtain the linear least-squares fit equation in the form:

(rspi) = (mi)(amti) + bi

where:

(rspi) = response ratio for oxygenate i (y-axis),

mi = slope of linear equation for oxygenate i,

amti = amount ratio for oxygenate i (x-axis), and

bi = y-axis intercept.

12.3.4 The values mi and bi are calculated as follows:

and

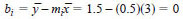

12.3.5 For the example in Table 3:

mi = 5 / 10 = 0.5

and

Therefore, the least-squares fit (see Eq 7) for the above example in Table 3 is:

(rspi) = 0.5 amti + 0

NOTE 1 - Normally the bi value is not zero and may be either positive or negative. Fig. 3 gives an example of a linear least-squares fit for MTBE and the resulting equation in the form of Eq 7.

12.3.6 For an optimum calibration, the absolute value of the y-intercept bi must be at a minimum. In this case, Ai approaches zero when wi is less than or equal to 0.1 mass %. The equation to determine the mass % oxygenate i or wi, reduces to Eq 13. The y-intercept can be tested using Eq 13:

wi = (bi/mi)(Ws/Wg)100 %

where:

wi = mass % oxygenate i, where wi is not more than 0.1 mass %,

Ws = mass of internal standard added to the gasoline samples, g, and

Wg = mass of gasoline samples, g.

NOTE 2 - Since in practice Ws and Wg vary slightly from sample to sample, use average values.

12.3.7 The following gives an example of the calculation for the y-intercept (bi) test using Fig. 3 for oxygenate i (MTBE) for which bi = 0.015 and mi = 1.83. From 13.1, a typical sample preparation may contain approximately Ws = 0.4 g (0.5 mL) of internal standard and approximately Wg = 7 g (9.5 mL) of a gasoline sample. Substituting these values into Eq 13 yields:

wi = (0.015/1.83)(0.4g/7g) 100 %

= 0.05 mass %

12.3.8 Since wi is less than 0.1 mass %, the y-intercept bi has an acceptable value for MTBE. Similarly, determine wi for all other oxygenates. For all oxygenates, wi must be less than or equal to 0.1 mass %. If any of the wi values are greater than 0.1 mass %, rerun the calibration procedure for oxygenate i or check instrument parameters and hardware or check for hydrocarbon interferences.