8. Procedure

8.1 Prepare nylon filters by heating in an oven at 105°C for 15 min. Cool and store the dried filters in a desiccator (without desiccant) until needed. Use only new filters.

8.2 Weigh the filter immediately before use to the nearest 0.0001 g.

8.3 Using tweezers, place the membrane filter on the center of the filter support, which is mounted on the filtering flask with a rubber stopper. Attach the reservoir to the filter support and clamp it securely.

8.4 Connect the heating coil to the circulating bath and place the coil around the lower part of the reservoir. Set the temperature of the circulating bath so as to maintain the oil in the reservoir at 90 +/- 2°C.

NOTE 4 - Care should be taken not to overheat the reservoir so as to cause evaporation of the toluene and glazing of the filter.

8.5 Into a 200-mL beaker, weigh 10 g of a thoroughly mixed sample (see Section 7) to the nearest 0.0001 g. Add 100 mL of toluene to the beaker and heat the mixture with stirring to 90 +/- 2°C. Maintain the temperature at 90 +/- 2°C for about 15 min to dissolve any wax in the crude.

8.6 Start the vacuum pump and adjust the vacuum to 200 mm Hg. Carefully pour the sample mixture into the filter reservoir in three portions. Generally the sample should filter in 10 to 15 min. If the nature of the crude or the amount of sediment causes the filtration to proceed extremely slowly (for example, filtering times greater than 30 min), reduce the sample size to 5 g or less and repeat the test. Keep the volume of toluene at 100 mL.

NOTE 5 - If the filtration of a given crude typically takes less than 10 min and the sample stays at 90 +/- 2°C during this time, then external heating of the filter reservoir may not be necessary.

8.7 Before the last portion of sample has completely filtered, wash the reservoir and filter with 50 mL of hot toluene (90°C) until no oil is visible on the filter. With the vacuum on, leave the filter on the apparatus for 2 min.

8.8 Disassemble the filter apparatus by removing the clamp and reservoir. Inspect the condition of the filter. If the filter has been properly mounted, it may not be necessary to wash the edges after disassembly. However, if upon removing the reservoir dark spots are observed around the edge of the filter further washing is necessary. With the vacuum on, use a dropper to wash the filter's edges with hot toluene (90°C).

8.9 If the filter is completely or partially covered with black or dark brown crude oil residue after the washing step above, then discard the filter and repeat the test with a smaller sample size.

NOTE 6 - Normally the color of the sediment on the filter is gray or light tan. A black or deep brown colored deposit on the filter is indicative of incomplete washing.

8.10 If the appearance of the filter is acceptable (as in 8.9) then carefully remove it and place it in an oven at 105°C for 15 min. Cool in a desiccator and reweigh to the nearest 0.0001 g.

9. Calculation

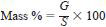

9.1 Calculate the mass percent of sediment as follows:

where:

G = gain in mass of filter, g, and

S = sample mass, g,