ASTM D4806 Standard Specification for Denatured Fuel Ethanol for Blending with Gasolines for Use as Automotive Spark-Ignition Engine Fuel

4. Performance Requirements

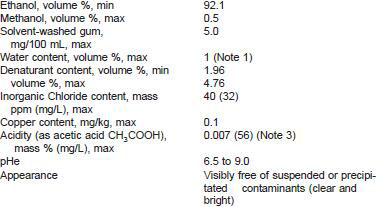

4.1 Denatured Fuel Ethanol - When fuel ethanol is denatured as specified in Section 5, it shall conform to the following requirements at the time of blending with a gasoline.

NOTE 1 - In some cases, a lower water content may be necessary to avoid phase separation of a gasoline-ethanol blend at very low temperatures. This reduced water content, measured at the time of delivery, shall be agreed upon between the supplier and purchaser.

NOTE 2 - If denatured fuel ethanol is prepared by the addition of denaturants to undenatured fuel ethanol after it has been produced rather than during the dehydration process, the 15.56/15.56°C (60/60°F) specific gravity in air of the undenatured fuel ethanol shall be in the range from 0.7937 - 0.7977.

NOTE 3 - Denatured fuel ethanol may contain additives such as corrosion inhibitors and detergents that may affect the titratable acidity (acidity as acetic acid) of the finished fuel ethanol. Although the base fuel ethanol may meet the acidity specification, the effect of these additives may produce an apparent high titratable acidity of the finished product. Contact the ethanol supplier if there is a question regarding the titratable acidity of your denatured fuel ethanol to verify that the base ethanol meets the acidity requirements of 4.1.

4.2 Other Properties - Limits more restrictive than those specified above, or the specification of additional properties such as color, may be agreed upon between the supplier and the purchaser.

5. Denaturants

5.1 The only denaturants used for fuel ethanol shall be natural gasoline, gasoline components, or unleaded gasoline at a minimum concentration of two parts by volume per 100 parts by volume of fuel ethanol, as defined by Formula CDA 20 of the Bureau of Alcohol, Tobacco, and Firearms (BATF) of the U.S. Treasury Department. This specification prohibits the use of hydrocarbons with an end boiling point higher than 225°C (437°F) as determined by Test Method D86, although they may be permitted by BATF regulations. Some kerosines, for instance, promote piston scuff in automotive engines. The denaturants permitted by this specification may be included as part of the 10 volume % denatured fuel ethanol blended with a gasoline if they do not exceed five parts by volume per 100 parts by volume of fuel ethanol. This is permitted in the United States by law. Any part of these denaturants that are present at concentrations higher than five parts by volume per 100 parts by volume of fuel ethanol are considered as part of the base gasoline.

NOTE 4 - BATF regulations concerning the preparation, use, and handling of denatured ethanols are published in the United States Code of Federal Regulations, Title 27, Parts 20 and 21. Part 20 contains primarily legal and administrative information, and Part 21 contains technical information on denaturants and denatured ethanols.

5.2 Prohibited Denaturants - Although this specification permits only hydrocarbons in the gasoline boiling range to be used as denaturants, specific mention must be made of some materials that have extremely adverse effects on fuel stability, automotive engines and fuel systems. These materials shall not be used as denaturants for fuel ethanol under any circumstances. They are as follows: methanol which does not meet Specification D1152, pyrroles, turpentine, ketones and tars (high-molecular weight pyrolysis products of fossil or nonfossil vegetable matter). While any significant amount of methanol will lower the water tolerance and increase the vapor pressure of a gasoline-ethanol blend, these effects become more serious when methanol is present at more than 2.5 parts by volume per 100 parts by volume of fuel ethanol. Also, methanol which does not meet Specification D1152 frequently contains impurities such as turpentine and tars. Similarly, ketone denaturants tend to degrade fuel stability or increase the tendency of a gasoline-ethanol blend to corrode metals and attack elastomers. These effects become more serious if the concentration of a ketone such as 4-methyl pentanone (methyl isobutyl ketone) exceeds one part by volume per 100 parts by volume of fuel ethanol. There is no information available on the effects of denaturants other than those mentioned above, but unless a denaturant, such as a higher aliphatic alcohol or ether, is known to have no adverse effect on a gasoline-ethanol blend or on automotive engines or fuel systems, it shall not be used.

6. Sampling

6.1 Samples may be obtained by an appropriate procedure of Practice D4057 or Practice E 300, except that water displacement (in section on Sampling for Specific Tests in D4057) must not be used. Where practical, fuel ethanol should be sampled in glass containers. If samples must be collected in metal containers, do not use soldered metal containers although they are specified in the Sampling Equipment section in Practice E 300. This is because the soldering flux in the containers may contaminate the sample.

6.2 Sample Size - A minimum of about 1 L or 1 U.S. qt is recommended. If specific gravity is to be determined by a hydrometer method, additional volume may be required. This depends on the size of the hydrometer.

6.3 Lot Size - A lot shall normally consist of the amount contained in a tanker compartment or other bulk container in which it is delivered. If this definition does not apply, the definition of a lot must be agreed upon between the supplier and purchaser.

NOTE 5 - See Sections 5, 6, and 7 of Practice E 300 for a detailed discussion of the statistics of sampling.