7. Hazards

7.1 Fumes of the solvents should be removed by means of proper hoods from all working areas. The working area should be kept free of sparks and flames. Quinoline fumes should not be inhaled, and prolonged contact with skin should be avoided.

7.2 Observe proper laboratory procedures for handling and diluting hydrochloric acid.

8. Bulk Sampling

8.1 Samples from shipments shall be taken in accordance with Practice D4296 and shall be free of foreign substances. Thoroughly mix the sample immediately before removing a representative portion for the determination or for dehydration.

9. Dehydration of Sample

9.1 Hard Pitch - If the solid bulk sample contains free water, air dry a representative portion in a forced draft oven at 122°F (50°C).

9.2 Soft Pitch (Softening Point <140°F (60°C)) - If the presence of water is indicated by surface foam on heating, maintain a representative portion of the bulk sample at a temperature between 257 and 302°F (125 and 150°C) in an open container until the surface is free of foam. Take care not to overheat, and remove the heat source immediately when the foam subsides.

9.3 Tar - A wet tar sample can either be dehydrated or used as received as long as conditions stated in 9.3.1 and 9.3.2 are met.

9.3.1 Dehydrate a representative portion of the bulk sample.

9.3.2 As an alternative to dehydration, the water content of the tar is determined by Test Method D95 and, if the water content is less than 10 weight %, the QI content is corrected to a dry-tar basis (see 13.2). This alternative method applies only to stable emulsions of water in tar, that is, no water separates when the tar sample is left undisturbed for 24 h at room temperature.

10. Preparation of Working Sample

10.1 Pitch that is sufficiently hard at room temperature shall be finely pulverized in a mortar. Crush this sample so that all of it will pass the 250-µm (No. 60) sieve. Soft pitches and tars shall be warmed and well agitated before sampling.

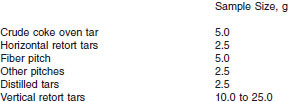

10.2 The amount of sample to be taken for the test shall be such that the final quantity of quinoline insoluble (QI) shall be not less than 0.1 g. As a guide, the following sample sizes are recommended:

10.2.1 When the sample contains 15 % QI or if the softening point is greater than 248°F (120°C), the amount used for testing should be reduced, but to not less than 0.5 g.

11. Crucible Preparation

11.1 If the crucible, after thorough cleaning (see 11.2), has been used for less than six determinations, clean it as follows. Remove the mat, wash the crucible with distilled water, dry, and ignite in a muffle furnace for 1 h at about 1472°F (800°C). Cool the crucible slowly by placing it in a drying oven for 1 h after removal from the furnace to prevent cracking and place it in a desiccator while still warm.

11.2 After the crucible has been used for six determinations, remove any residual ash from pores in the filtering area by boiling in 1 + 1 hydrochloric acid solution. Refer to 6.2. Then boil the crucible in distilled water, thoroughly back wash with distilled water, dry, and ignite as in 11.1.