8. Procedure

8.1 Sample Preparation:

8.1.1 Determine the mass of each clean sample vial being used in the sample analysis, and record the mass to nearest 0.1 mg.

8.1.2 During weighing and filling, handle vials with forceps to help minimize weighing errors. Discard the sample vials after use.

8.1.3 It is assumed that a representative sample of the stock or process has been obtained for laboratory use following Practice D4057 or similar standard. Stir the sample to be tested, first warming if necessary to reduce its viscosity. Samples that are homogeneous liquids can be transferred directly to vials using a rod, syringe, or eyedropper. Solid materials may also be heated; or frozen with liquid nitrogen, and then shattered to provide manageable pieces.

8.1.4 Transfer an appropriate mass of the sample (see Table 1) into a tared-sample vial, reweigh to nearest 0.1 mg, and record. Place the loaded sample vials into vial holder (up to twelve), noting position of each sample with respect to index mark.

NOTE 2 - A control sample can be included in each batch of samples being tested. This control sample should be a typical sample that has been tested at least 20 times in the same equipment in order to define an average percent carbon residue and standard deviation. Results for each batch are deemed acceptable when results for the control sample fall within the average percent carbon residue more or less three standard deviations. Control results that are outside these limits indicate problems with the procedure or the equipment.

8.2 Processing of Samples:

8.2.1 With the oven at less than 100°C, place the vial holder into the oven chamber and secure lid. Purge with nitrogen for at least 10 min at 600 mL/min. Then decrease the purge to 150 mL/min and heat the oven slowly to 500°C at 10°–15°C/min.

8.2.2 If the sample foams or spatters, causing loss of sample, discard and repeat the test.

NOTE 3 - Spattering may be due to water that can be removed by prior gentle heating in a vacuum, followed by a nitrogen sweep. Alternatively, a smaller sample size can be used.

8.2.3 Hold oven at 500 more or less 2°C for 15 min. Then shut off furnace power and allow oven to cool freely while under nitrogen purge of 600 mL/min. When oven temperature is less than 250°C, remove the vial holder for further cooling in desiccator. After the samples are removed from the oven, the nitrogen purge may be shut off. (Warning - Do not open oven to air at any time during the heating cycle. The introduction of air (oxygen) will likely cause the sample to ignite and spoil the test. (Because of the oven design and materials, such an ignition is normally not a hazard to the operator.) Open the oven only after oven temperature falls below 250°C during the cooling step. Maintain nitrogen flow until after the vial holder has been removed from the oven.) (Warning - Locate the coking oven in laboratory exhaust hood for safe venting of smoke and fumes. Alternatively, install vent line from MCRT oven exhaust to laboratory exhaust system.) (Warning - If a vent line is used, do not connect directly to exhaust chimney to avoid creating negative pressure in the line.)

NOTE 4 - To reduce oven temperature for the next run, remove the oven lid to allow faster cooling. As required by the procedure, the subsequent test can be started when the oven has been cooled to below 100°C.

8.3 Final Weighing - Transfer sample vials (maintained in place in the vial holder) to desiccator and allow vials to cool to room temperature. Weigh the cooled vials to the nearest 0.1 mg and record. Handle the vials with forceps. Discard the used glass sample vials.

8.4 Occasionally examine the condensate trap at the bottom of the oven chamber; empty if necessary and replace. (Warning - The condensate trap residue may have some carcinogenic materials present. Avoid contact with the trap residue; dispose of it in accordance with local laboratory practice.)

9. Procedure for Carbon Residue on 10 % (V/V) Distillation Residue 9.1 This procedure is applicable to light distillate materials, such as ASTM No. 1 and No. 2 fuel oil or materials expected to have less than 0.1 % (m/m) carbon residue.

9.2 A distillation analysis using either a 100 or 200-mL starting volume is required in order to collect a sufficient amount of the 10 % (V/V) residue needed in this analysis. For a 100-mL distillation, assemble the distillation apparatus described in Specification E 133, using flask B (125-mL bulb volume), flask support board with 50-mm diameter opening, and graduated cylinder B (100-mL capacity). For a 200-mL distillation, assemble the distillation apparatus described in Specification E 133, using flask D (250-mL bulb volume), flask support board with 50-mm diameter opening, and graduated cylinder C (200-mL capacity). A thermometer is not required, but the use of the ASTM High Distillation Thermometer 8F or 8C, as prescribed in Specification E 1, or the IP High Distillation Thermometer 6C, as prescribed in the Specification for IP Thermometers, is recommended.

9.3 Depending upon which distillation flask is used, place either 100 or 200 mL of sample (as measured at ambient temperature) into a tared distillation flask that is held at a temperature between 13°C and ambient, and record the mass of sample transferred (E1). Maintain the condenser bath temperature between 0 and 60°C so as to provide a sufficient temperature differential for sample condensation, while avoiding any solidification of waxy material in the condenser tube. Use, without cleaning, the cylinder from which the sample was measured as the receiver, and place it so that the tip of the condenser does not touch the wall of the cylinder. The receiver temperature is required to be maintained at the same temperature (within more or less 3°C) as the sample taken at the start of the test in order to obtain an accurate volume measurement in the receiving flask.

9.4 Apply the heat to the flask at a uniform rate so regulated that the first drop of condensate exits from the condenser between 10 and 15 min (for 200-mL samples) or between 5 and 15 min (for 100-mL samples) after initial application of heat. After the first drop falls, move the receiving cylinder so that the tip of the condenser tube touches the wall of the cylinder. Then regulate the heat so that the distillation proceeds at a uniform rate of 8 to 10 mL/min (for 200-mL samples) or 4 to 5 mL/min (for 100-mL samples). For 200-mL samples, continue the distillation until approximately 178 mL of distillate has been collected, and then discontinue heating and allow the condenser to drain until 180 mL (90 % (V/V) of the charge to the flask) has been collected in the cylinder. For 100-mL samples, continue the distillation until approximately 88 mL of distillate has been collected, and then discontinue heating and allow the condenser to drain until 90 mL (90 % (V/V) of the charge to the flask) has been collected in the cylinder.

9.5 Catch final drainage, if any, by immediately replacing the cylinder with a suitably tared container, such as a small Erlenmeyer flask. Add to this container, while still warm, the distillation residue left in the distilling flask, and mix well. The contents of the container then represents a 10 % (V/V) distillation residue from the original product. Allow the contents of the container to cool to ambient temperature before weighing the container and its contents in order to obtain an accurate measurement.

9.6 If the distillation residue is too viscous to flow freely at ambient temperature, it is necessary to warm the distillation residue to a sufficient temperature that will allow a portion of the material to be transferred into a previously weighted vial for analysis (see Table 1). After allowing the material in the vial to cool to ambient temperature, determine the mass of the test specimen to the nearest 0.1 mg and carry out the carbon residue test in accordance with the procedure described in Section 8.

10. Calculation

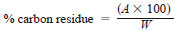

10.1 Calculate the mass % carbon residue in the original sample, or in the 10 % distillation bottoms as follows:

10.1.1 Calculate percent residue as follows:

where:

A = carbon residue, g, and

W = sample used, g.