ASTM D446 standard specifications and operating instructions for glass capillary kinematic viscometers

7. Kinematic Viscosity Calculation

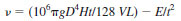

7.1 Basic Formula:

7.1.1 Kinematic viscosity, expressed in mm2/s, can be calculated from the viscometer dimensions as follows:

where:

n = the kinematic viscosity, mm2/s,

g = the acceleration due to gravity, m/s2,

D = the diameter of the capillary, m,

L = the length of the capillary, m,

H = the average distance between the upper and lower menisci, m,

V = the timed volume of liquids passing through the capillary, m3(approximately the volume of the timing bulb),

E = the kinetic energy factor, mm2•s, and

t = the flow time, s.

7.1.2 If the viscometer is selected so that the minimum flow time shown in the tables of Annex A1, Annex A2, and Annex A3 are exceeded, the kinetic energy term, E/t2, becomes insignificant and Eq 4 may be simplified by grouping the non-variable terms into a constant, C, as follows:

v = C•t

7.2 Kinetic Energy Correction:

7.2.1 The viscometers described in the Annex A1, Annex A2, and Annex A3 are designed such that the kinetic energy correction term, E/t2, is negligible if the flow time is more than 200 s. In the case of several sizes of viscometers for the measurement of low-kinematic viscosity liquids, a minimum flow time greater than 200 s is required in order that the kinetic energy correction term, E/ t2, shall be negligible. The minimum flow times required are set out as footnotes to the appropriate tables of viscometer dimensions given in the Annex A1, Annex A2, and Annex A3.

7.2.2 For viscometers whose constants are 0.05 mm2/s2 or less, a kinetic energy correction can be significant if the minimum 200 s flow is not observed. Where this is not possible, Eq 5 takes on the following form:

kinematic viscosity, mm2/s 5 Ct – E/t2

where:

E = kinetic energy factor, mm23 s,

C = viscometer constant, mm2/s2,

t = flow time, s.

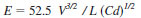

7.2.3 Although the kinetic energy factor, E, is not a constant, it may be approximated by means of the following equation:

where:

(using the units given in Figs. A1.1-A3.4)

V = volume of the timing bulb, mL,

L = capillary working length, mm,

d = capillary working diameter, mm,

C = viscometer constant, mm2/s2.

NOTE 1 - The kinetic energy factor for certain viscometer designs and flow time use can result in significant kinematic viscosity errors. Determine the effect of the kinetic energy factor for viscometers not described in this specification.

7.3 Maximum Flow Time:

7.3.1 The limit of 1000 s has been set arbitrarily for convenience as the recommended maximum flow time for the viscometers covered by this standard. Longer flow times may be used.

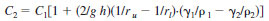

7.4 Surface Tension Correction:

7.4.1 If the two menisci have different average diameters during the flow time and if the surface tension of the sample differs substantially from the calibrating liquid, a surface tension correction is necessary. The changed C constant, C 2, is given approximately as follows:

where:

g = the acceleration due to gravity, m/s2,

h = the average driving head, m,

ru = the average radius of the upper meniscus, m,

rl = the average radius of the lower meniscus, m,

g = the surface tension, N/m, and

r = the density, in kg/m3.

Subscripts 1 and 2 relate to values with the calibrating liquid and the test portion, respectively.

7.4.2 While this correction applies to all viscometers, a number of viscometers are designed to minimize the surface tension correction. The greatest correction normally encountered is with a viscometer calibrated with water and used for oils. Generally, viscometers are calibrated and used with hydrocarbons whose surface tensions are close enough for these corrections to be insignificant.

7.5 Effect of Temperature:

7.5.1 The viscometer constant, C, is independent of temperature for all those viscometers which have the volume of sample adjusted at bath temperature and in the case of all suspended-level viscometers.

7.5.2 The following viscometers, which have a fixed volume charged at ambient temperature, have a viscometer constant, C, which varies with temperature: Cannon-Fenske routine, Pinkevitch, Cannon-Manning semi-micro, Cannon-Fenske opaque.

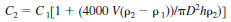

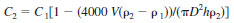

7.5.3 The following equation can be used to calculate the viscometer constant at temperatures other than the calibration temperature for the Cannon-Fenske routine, Pinkevitch, and Cannon-Manning semi-micro viscometers:

where:

C1 = the constant of the viscometer when filled and calibrated at the same temperature,

V = the volume of charge, mL,

D = the average diameter of the meniscus in the lower reservoir for the Cannon-Fenske routine, Pinkevitch, and Cannon-Manning semi-micro viscometers, and in the upper reservoir of the Cannon-Fenske opaque viscometer, mm,

h = the average driving head, mm,

ρ1 = the density of the test liquid at the filling temperature, kg/m3 x 10(-3), and

ρ2 = the density of the test liquid at the test temperature, kg/m3 x 10(-3).

7.5.4 The temperature dependence of C for the Cannon-Fenske opaque (reverse-flow) viscometer is given as follows:

8. Keywords

8.1 kinematic viscosity; viscometer; viscosity