ASTM D4425 standard test method for oil separation from lubricating grease by centrifuging (Koppers Method)

10. Calculation

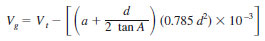

10.1 Calculate the grease volume to the nearest cm3 as follows:

where:

Vg = grease volume, cm3,

Vt = tube volume, cm3 (see 9.1.1),

a = distance to grease surface, mm (see 9.7),

d = tube inside diameter, mm (see 9.1.2), and

A = angle of the rotor, in degrees. This angle is specified by the rotor manufacturer.

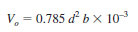

10.2 Calculate the oil volume to the nearest cm3 as follows:

where:

Vo = separated oil volume, cm3, and

b = height of the separated oil, mm (see 9.10).

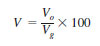

10.3 Calculate the amount of oil separated from the grease to the nearest percent as follows:

where

V = oil separation, in volume percent.

11. Report

11.1 The amount of oil separated from a lubricating grease subjected to centrifugal forces is a function of the G level, the amount of time under test, and the test temperature. Thus, to evaluate the resistance of a grease to separate the oil, the following data are required:

11.1.1 The oil separation, in volume percent (see 10.3).

11.1.2 The level of centrifugal acceleration, in G (see 3.1).

11.1.3 The duration of the test, in hours.

11.1.4 The test temperature, in °Celsius.

11.2 In order to simplify the testing and reporting of the oil separation from lubricating greases by centrifuging, the level of centrifugal acceleration and the test temperature are maintained constant, at a G value of 36000 and 50°C. Hence, the resistance of a grease to separate the oil under centrifugal forces is reported as the fraction K36.

K36 = V/H

where:

V = oil separation, in volume percent (see 10.3), and

H = accumulated time of testing in hours (see 9.13).

The fraction K36 should not be reduced, and the values of both V and H should be reported.

11.3 The results of two tubes filled with the same grease (see 9.3) are averaged for reporting purposes.

11.4 The values for V and H in Eq 6 are those at the time the oil separation stabilizes. This is defined as the time at which the oil separation increases by less than 10 % between two consecutive readings.

11.4.1 If the oil separation does not stabilize before the 24 h test, the 24 h test results are used for reporting.

11.4.2 If the testing is extended beyond the 24 cumulative hours, the same conditions in 11.4 apply, except more than 24 h can be used. Examples of calculations can be found in Appendix X1.

12. Precision and Bias

12.1 Precision - When run under the conditioins stated in the test method, the precision, as determined by statistical examination of interlaboratory results is as follows:

12.1.1 Repeatability - The difference between successive test results, obtained by the same operator with the same apparatus under constant operating conditions on identical test material, would in the long run, in the normal and correct operation of the test method, exceed 4.8 percentage points (of the value of V, 10.3) only in one case in twenty.

12.1.2 Reproducibility - The difference between two single and independent results, obtained by different laboratories on identical test material, would in the long run, in the normal and correct operation of test method, exceed 18.7 percentage points (of the value V, 10.3) only in one case in twenty.

12.2 Bias - The procedure in this test method has no bias because the value of K36 can be defined only in terms of the test method.

13. Keywords

13.1 centrifuge; grease; lubricating grease; oil separation