ASTM D4306 standard practice for aviation fuel sample containers for tests affected by trace contamination

6. Preparation of Apparatus

6.1 Introduction:

6.1.1 Experience indicates no single container type to meets all desired requirements including size and cost. Certain container types have been found suitable for some test methods but not for others. Some containers are adequate if the samples are used immediately but are not suitable for sample storage. The procedure therefore designates the containers to be used for each test procedure and describes prior cleaning, if any. A summary of the procedures is found in Table 1. The detailed procedures follow below. However, the possibility that a fuel may contain an unusual contaminant, making a normally satisfactory container unsuitable should not be overlooked.

6.1.2 The largest sample meeting shipping rules, costs, availability, and other practical considerations should always be used to minimize surface effects.

6.1.3 It is not possible to describe some of the container materials by standard specifications or by suitable generic descriptions. Therefore, an approval procedure is outlined in 6.2.

6.1.4 Other sampling details such as sampling taps, labelling, shipping instructions, and so forth will be found in Practice D4057.

6.2 Approval Procedure (Stored Samples):

6.2.1 If internally coated the new container should be examined visually for coating integrity in accordance with 4.1.1.2 and closure suitability in accordance with 4.2.1.

6.2.2 Containers should be flushed three times with the container 10 to 20 % filled with trisolvent (equal volumes of 5.1, 5.2, and 5.3), then three times with heptane. For each flush, the container should be closed and shaken for 1 min and the solvent replaced for the next flush. After the last flush is drained, the container should be air-dried.

6.2.3 Reference fuel as indicated in 5.3 should be used for testing.

6.2.4 The containers should be filled with reference Jet A, or A-1, closed, and stored for at least one month at room temperature. During this period the samples should be shaken strongly at least once a week. At the end of storage the sample should be tested for electrical conductivity and water separation. The final electrical conductivity should be no more than 2 pS/m greater than the original value. The water separation rating should decrease by no more than three MSEP units.

6.2.5 Supplemental testing is necessary if the fuel normally contains additives such as conductivity improvers which may be desorbed. In that case a large additive-containing sample which has been stored for a month or longer to equilibrate additive content should be used as the test fuel. Such fuel should have a conductivity above 50 pS/m if the additive is conductivity improver additive; and the MSEP value should also be determined. After similar storage for at least one month, the final electrical conductivity should not change more than the repeatability limits of Test Method D2624 or D4308, whichever method is used to rate the fuel. The final MSEP rating should be within the repeatability limits for the initially obtained value.

6.2.6 The large container fuel sample should preferably be retained in its original container as a reference sample during the storage interval, and retested to determine whether a correction, equal to any change in the reference material, should be applied. Similar testing can be applied for other additives and properties.

6.3 Approval Procedure (Immediate Use):

6.3.1 All containers found suitable for storage are suitable for immediate use. The following procedure applies to circumstances where fuel samples will not be retained for longer than 24 h, preferably for shorter times.

6.3.2 The approval procedure is identical to that for storage except that the elapsed time interval between filling containers and testing should be not less than 24 h.

NOTE 3 - Effects due to containers are sometimes variable depending on fuel sample properties especially if additives are present. Evaluations with several fuels or fuel types are helpful to verify conclusions.

6.4 Containers for Thermal Stability Testing:

6.4.1 Epoxy-lined containers in accordance with 4.1.1 are preferred for immediate testing or sample storage. New containers should be flushed three times with product being sampled.

6.4.1.1 Used containers should be flushed three times with the container 10 to 20 % filled with trisolvent (6.2.2) or heptane. For each flush the container should be closed and shaken for 1 min and the solvent replaced for the next flush. After the last flush is drained, the container should be air dried. Alternately, borosilicate glass bottles can be similarly rinsed three times with the fuel to be tested, then drained.

6.4.1.2 If the same fuel type containing the same additives is to be resampled, flushing three times with the new sample is considered adequate preparation as per flushing instruction provided in 6.5.1.

6.4.2 New borosilicate glass bottles are satisfactory for immediate use if cleaned by rinsing with water, acetone, and air drying. Amber bottles are preferred. Clear bottles must be shielded from light by wrapping with aluminum foil or enclosure in a dark box or cabinet.

6.4.3 New tin-plated cans with soldered side seams should only be used if the container is cleaned and the sample is used immediately.

6.4.3.1 Cleaning Before Use - Half fill the container with acetone. Alternatively, a mixture of equal volumes of acetone, toluene, and isopropanol may be used. Replace closure and shake vigorously for 1 min. Drain the solvent and air dry. Fill the container about 1/4 full with heptane, replace closure and repeat shaking, draining the solvent and air drying the container.

NOTE 4 - Soldered cans often contain residues of soldering flux or roll-oils on inside surfaces. These materials may have low solubility in hydrocarbons but even at trace levels will adversely affect the properties discussed in this practice. The difficulties of completely removing these contaminants make the use of epoxy-lined containers preferable.

6.4.4 PTFE bottles have not been evaluated but should be satisfactory after cleaning with heptane in accordance with 6.4.1.1.

6.4.5 Other plastic bottles such as high-density linear polyethylene have not been evaluated and are not recommended.

6.5 Containers for Water Separation Testing:

6.5.1 Epoxy-coated containers, whether new or used, are preferred for immediate testing or sample storage. Immediately prior to sample collection, flush the container three times with the sample being collected. For each flush, the container should be 10 to 20% filled with sample, closed, and shaken for a minimum of 5 s and the fuel replaced for the next flush. After the last flush is drained, the container may be filled for transport to the laboratory for testing.

6.5.1.1 Used containers can be reused after cleaning in accordance with 6.4.1.1 or 6.4.1.2.

6.5.1.2 If the same fuel type containing the same additives is to be sampled, flushing the container three times with the new product is considered adequate preparation.

6.5.2 Borosilicate glass bottles are preferred for immediate use and storage, after rinsing with water, acetone, and air drying. Follow the instruction in 6.4.1.1 and 6.4.1.2 for reusing borosilicate bottles. Alternately, borosilicate glass bottles can be similarly rinsed three times with the fuel to be tested, then drained.

6.5.3 Tin-plated, side-seam soldered cans are satisfactory for immediate use after cleaning according to 6.4.1.1 or 6.4.1.2.

6.5.4 PTFE bottles have not been evaluated but should be satisfactory after cleaning with heptane in accordance with 6.4.1.1. For re-cleaning, bottles should be filled with low-conductivity toluene and allowed to soak overnight (more than 16 h). The conductivity of the toluene should not have increased more than 20 pS/m following this soak; if it has, repeat soak. Empty and air dry.

6.5.5 Hard linear polyethylene bottles have been used satisfactorily for immediate use, but it is necessary to evaluate a particular manufacturer's product (bottles and closures) in accordance with 6.2, using Test Method D3948 to evaluate the containers.

6.5.6 Soft glass bottles (soda lime bottles) are satisfactory for some immediate use and storage if they have been soaked overnight with deionized water, emptied, rinsed with acetone, and dried. Follow 6.4.1.1 and 6.4.1.2 for cleaning or reusing soft glass bottles.

6.5.7 Aluminum containers are not satisfactory.

6.6 Containers for Electrical Conductivity Testing:

6.6.1 Epoxy-coated containers, whether new or used, are preferred for immediate testing or sample storage. Immediately prior to sample collection, flush the container three times with the sample being collected. For each flush, the container should be 10 to 20% filled with sample, closed, and shaken for a minimum of 5 s and the fuel replaced for the next flush. After the last flush is drained, the container may be filled for transport to the laboratory for testing.

6.6.1.1 Epoxy-coated containers can be reused after cleaning in accordance with 6.4.1.1 or 6.4.1.2.

6.6.1.2 If the same fuel type containing the same additives is to be sampled, flushing the used container three times is considered satisfactory preparation.

6.6.2 Borosilicate glass bottles are preferred for immediate use or storage of samples. Prepare containers by rinsing with water, acetone, and air drying, or by rinsing with hot water followed by deionized water and air drying. Follow the instruction in 6.4.1.1 or 6.4.1.2 for cleaning or reusing borosilicate bottles. Alternately, borosilicate glass bottles can be similarly rinsed three times with the fuel to be tested, then drained.

6.6.3 PTFE bottles are not recommended.

6.6.4 Tin-plated, side-seam soldered containers have been satisfactory after cleaning in accordance with 6.4.3.1.

6.6.5 Hard linear polyethylene bottles are not recommended.

6.6.6 Soft glass bottles (soda lime bottles) are satisfactory for immediate use if they have been soaked overnight with deionized water, emptied, rinsed with acetone, and dried. Alternatively, rinse with hot water, then deionized water or acetone, and air dry. Follow 6.4.1.1 and 6.4.1.2 for cleaning or reusing soft glass bottles.

6.6.7 Aluminum containers are not satisfactory.

NOTE 5 - Although this practice attempts to minimize container effects wherever possible, electrical conductivity tests should be carried out directly on fuel in tankage or by drawing a sample for immediate testing.

NOTE 6 - Conductivity of fuels is known to change during storage. Results obtained on shipped samples may not be a reliable indicator of the fuel's actual conductivity level. Therefore using shipped samples for conductivity measurements is not recommended. Supplemental testing as discussed in 6.2.5 is useful only to qualify containers. See Test Method D2624.

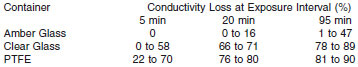

NOTE 7 - Studies have shown that exposure to sunlight can cause dramatic, permanent loss in the conductivity of fuels containing conductivity improving additives. This has been demonstrated in borosilicate glass and in UV-transparent PTFE bottles, and probably occurs in any UV-transparent container. The following data were obtained for three kerosine jet fuel samples with conductivities of 385 to 550 pS/m, in 500 mL borosilicate glass or PTFE containers after exposure to Mid-Atlantic summer sunlight. Slower loss is expected from fluorescent lights or other less intense UV sources. Similar effects were noted with various additives. Amber glass bottles are less affected.

6.7 Containers for Lubricity Testing:

6.7.1 Closures for bottles, cans, or other types of containers that have wax or plastic coatings in contact with the sample are unsatisfactory for samples to be tested for lubricity.

6.7.2 Epoxy-coated containers, whether new or used, are preferred for immediate testing or sample storage. Immediately prior to sample collection, flush the container three times with the sample being collected. For each flush, the container should be 10 to 20% filled with sample, closed, and shaken for a minimum of 5 s and the fuel replaced for the next flush. After the last flush is drained, the container may be filled for transport to the laboratory for testing.

6.7.2.1 For storage of samples, the displacement of air above the sample with nitrogen is recommended.

6.7.2.2 Epoxy-coated containers can be reused if cleaned in accordance with 6.4.1.1 or 6.4.1.2.

6.7.3 Borosilicate glass bottles have been found satisfactory after cleaning as follows:

6.7.3.1 Fill the bottle with 1 weight % solution of laboratory detergent in accordance with 5.5 in tap water, replace closure and allow to soak for at least 10 min.

6.7.3.2 Vigorously scrub all bottle and closure surfaces with detergent solution.

6.7.3.3 Repeatedly rinse bottle and closure with hot tap water (60 to 75°C) until last tendency toward foam formation has disappeared.

6.7.3.4 Generously wet the closure and allow to soak for at least 10 min.

6.7.3.5 Add hot tap water (60 to 75°C) and repeat scrubbing and rinsing procedure until foaming tendency disappears.

6.7.3.6 Rinse twice more with hot distilled water (60 to 75°C).

6.7.3.7 Oven dry the bottle and closure separately at 115 to 125°C.

6.7.3.8 After cooling, replace closure.

6.7.4 Tin-plated, side-seam soldered containers are not satisfactory.

6.7.5 PTFE containers are not satisfactory.

6.7.6 Other plastic containers are not recommended.

6.8 Containers for Trace Metal Analysis:

6.8.1 New PTFE or high-density linear polyethylene bottles, flushed three times with the product to be sampled are preferred for immediate testing, shipping, or sample storage.

6.8.1.1 These containers can be reused if cleaned in accordance with 6.4.1.1 or 6.4.1.2.

6.8.2 Epoxy-coated containers have not been tested extensively for this purpose and may be less suitable.

6.8.3 Glass or metal containers are not recommended because of possible surface wetting by metal-containing water or because of the transfer of metals, particularly sodium, into the sample.

6.9 Containers for Copper Corrosion Testing:

6.9.1 Epoxy-coated containers, whether new or used, are preferred for immediate testing or sample storage. Immediately prior to sample collection, flush the container three times with the sample being collected. For each flush, the container should be 10 to 20% filled with sample, closed, and shaken for a minimum of 5 s and the fuel replaced for the next flush. After the last flush is drained, the container may be filled for transport to the laboratory for testing.

6.9.1.1 Epoxy-coated containers can be reused if cleaned in accordance with 6.4.1.1 or 6.4.1.2.

6.9.2 Hard borosilicate glass bottles are suitable for immediate use or sample storage if dark in color or if wrapped in aluminum foil or other opaque material to avoid exposure to light.

6.9.3 PTFE or high density polyethylene bottles are suitable for immediate use or storage if protected from exposure to light by wrapping in aluminum foil or other opaque material.

6.9.4 Tin-plated soldered steel containers are not recommended.

6.10 Containers for Particulate Content Testing:

6.10.1 Epoxy-coated containers, whether new or used, are preferred for immediate testing or sample storage. Immediately prior to sample collection, the container should be flushed three times with the sample being collected. For each flush, the container should be 10 to 20% filled with sample, closed, and shaken for a minimum of 5 s and the fuel replaced for the next flush. After the last flush is drained, the container may be filled for transport to the laboratory for testing.

6.10.1.1 Used containers may be reused after cleaning in accordance with 6.4.1.1 or 6.4.1.2.

6.10.1.2 If the same fuel type containing the same additives is to be resampled, flushing three times with the new sample is considered adequate preparation as per flushing instruction provided in 6.5.1.

6.10.2 Although epoxy-coated cans are considered to be the industry standard for transporting samples for Test Method D5452 testing, other containers may be used if they are demonstrated to impart no bias to Test Method D5452 results.

7. Keywords

7.1 aviation fuels; containers, sampling; containers, shipping; turbine fuels