ASTM D4290 standard test method for determining the leakage tendencies of automotive wheel bearing grease under accelerated conditions

12. Report

12.1 Report the leakage to the nearest 0.1 g as determined in 10.13.

12.2 Report other observations such as grease movement in the hub, condition of the bearings, and so forth.

12.3 Report the presence on the bearing surface of any adherent deposit of varnish, gum, or lacquer-like material, which is evident after removal of the grease.

NOTE 7 - With some wheel bearing greases, it will be found that grease thickeners are not completely washed from the bearings with ASTM n-heptane. A film of grease thickener may, therefore, remain on the bearings. This film can be readily distinguished from varnish, gum, or lacquer-like deposits resulting from deterioration of the lubricant.

13. Precision and Bias

13.1 Precision - The precision of this test method was determined by statistical examination of interlaboratory results. In 1988 a more precise bearing packing procedure was included in 10.3. The precision data shown was obtained earlier using a less detailed packing procedure:

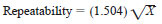

13.1.1 Repeatability - The difference between two test results obtained by the same operator with the same apparatus under constant operating conditions on identical test material would, in the long run, in the normal and correct operation of the test method, exceed the following values in only one case in twenty.

where:

X = the average of the two test results.

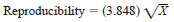

13.1.2 Reproducibility - The difference between two single and independent results obtained by different operators working in different laboratories on identical test material would, in the long run, in the normal and correct operation of the test method, exceed the following values in only one case in twenty.

where:

X = the average of the two test results.

13.2 Bias - The procedure in Test Method D4290 for measuring the leakage tendencies of automotive wheel bearing greases under accelerated conditions has no bias because the value of grease leakage can be defined only in terms of the test method.

NOTE 8 - A round robin of eleven cooperators testing five greases has resulted in the precision statement shown above. The data are shown in Table X1.1 of Appendix X1. In this round robin, determinations were made using testers by Pam and by Koehler. No distinction was made as both testers gave equivalent results.

14. Keywords

14.1 leakage automotive wheel bearing; lubricating grease; wheel bearing grease