10. Report

10.1 Report, as mean mass loss, the mean, to one-tenth mg, of the two mass losses determined in 9.10.

11. Precision and Bias

11.1 The precision of the mean mass losses as determined by the statistical examination of interlaboratory test results is as follows:

NOTE 9 - The data used to develop the precision statement were obtained from cooperative tests using n-hexane and chloroform instead of the prescribed solvents. n-Heptane and 1,1,1-trichloroethane are now prescribed because of their less hazardous nature. A limited study indicated that test results are not affected by this substitution.

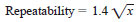

11.1.1 Repeatability - The difference between two test results, obtained by the same operator with the same apparatus under constant operating conditions on identical test material would, in the long run, in the normal and correct operation of the test method, exceed the following values only in one case in twenty (see Table 1).

where x = average mean mass losses of two tests in milligrams.

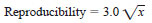

11.1.2 Reproducibility - The difference between two single and independent results obtained by different operators working in different laboratories on identical test material would, in the long run, in the normal and correct operation of the test method, exceed the following values only in one case in twenty.

where x = average mean mass losses of two tests in milligrams.

11.1.3 The mass loss ratios are not subject to precision analysis. However, mass loss ratios were determined in the interlaboratory test program. The following ranges of mass loss ratios were observed:

11.2 Bias - The procedure in this test method has no bias because the value of fretting wear can be defined only in terms of a test method.

12. Keywords

12.1 Fafnir test; false brinelling; fretting corrosion; fretting wear; friction oxidation; grease; lubricating grease; oscillating wear test; wear