11. Calibration

11.1 Chromatograms of Aroclors 1242, 1254, and 1260 together contain all the peaks normally found in Aroclor mixtures. These three materials may, therefore, be used as standards for routine quantitative analysis of PCB contamination of insulating fluids. Other Aroclors (for example 1016, 1248, etc.) standards may be useful for identification purposes, but are not needed in quantifying the results.

11.2 Aroclor 1242 contains virtually no PCB substituted with seven or eight chlorines and Aroclor 1260 contains virtually no mono-, di-, tri-, or tetrachlorobiphenyls. Analysis of mixtures of the total range of mono- to octa-substituted biphenyls requires calibration based on standard test specimens of Aroclor 1242, Aroclor 1254, and Aroclor 1260.

11.3 Dissolve a carefully weighed amount of a standard Aroclor in a measured amount of solvent (see 11.3.1 and 11.3.2) to give a solution containing approximately 1 mg/mL. Additional dilutions may be required to obtain a working stock solution for preparation of working standards. The exact weight of the Aroclor and the total volume of the final solution should be recorded as Ws, g and Vs, mL.

11.3.1 Mineral Insulating Oil Test Specimens - Use a stock solution of mineral oil in solvent to prepare standards for analysis of mineral oil test specimens, made by dissolving 10 to 20 g of the appropriate mineral insulating oil per 1 L of pesticide-grade solvent. The precise amount of oil should be chosen to give the same solvent-to-oil ratio in standards as that to be obtained on diluting test specimens to be analyzed (see 12.3). The ratio of solvent-to-oil should not be less than 50:1.

11.3.2 Silicone Insulating Liquid Test Specimens - Use pesticide-grade solvent alone to prepare standards for analysis of silicone liquid test specimens.

11.3.2.1 The most convenient method of preparing the standard for injection is to dilute a commercially available solution of known concentration. Otherwise, it is necessary to prepare the standard by progressive dilutions. The amount of oil in the stock solution may require adjustment if the commercial standard solution is very dilute.

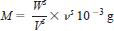

11.4 Inject a volume, ns, µL, of the diluted Aroclor standard into the chromatograph. Recommended injection volumes range from 1 to 5 µL, depending on individual detector response and anticipated sample injection volume (12.5). The quantity of PCB injected, M, g, is as follows:

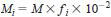

Identify each peak by comparison with the relative retention times given in Table 1, Table 2, and Table 3 or by comparison with the chromatograms in Fig. 1, Fig. 2, and Fig. 3. The quantity of PCB represented by each peak, Mi, g, is

11.4.1 Values of fi are given in Table 1, Table 2, and Table 3.

11.4.2 Values of M should be less than 10 ng to avoid overloading the detector with a resulting loss in sensitivity.