ASTM D4052 standard test method for density, relative density, and API gravity of liquids by digital density meter

15. Precision and Bias

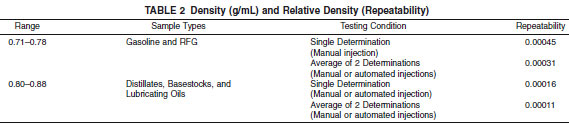

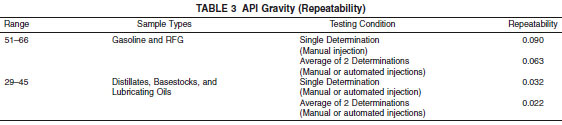

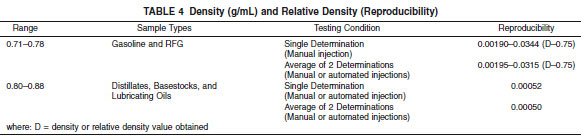

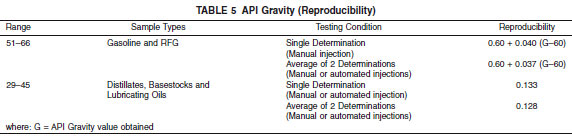

15.1 The precision of the method as obtained by statistical examination of interlaboratory test results at a test temperature of 15°C is as follows for the following sample types and ranges:

15.1.1 Repeatability - The difference between successive test results obtained by the same operator with the same apparatus under constant operating conditions on identical test material, would in the long run, in the normal and correct operation of the test method, exceed the following value only in one case in twenty:

15.1.1.1 Density (g/mL) and Relative Density - See Table 2.

15.1.1.2 API Gravity - See Table 3.

15.1.2 Reproducibility - The difference between two single and independent results, obtained by different operators working in different laboratories on identical test material, would in the long run, in the normal and correct operation of the test method, exceed the following values only in one case in twenty:

15.1.2.1 Density (g/mL) and Relative Density - See Table 4.

15.1.2.2 API Gravity - See Table 5.

NOTE 6 - The ASTM Interlaboratory Study (ILS) conducted in Fall 1999 involved 11 labs and 23 samples. The samples included 5 motor gasolines, 1 motor gasoline + ethanol, 4 reformulated gasolines (RFG), 2 lube oils, 1 basestock oil, 4 Jet-A fuels, 1 JP8 fuel, and 5 diesel fuels. The ILS protocol required labs to perform a total of four measurements per sample, which included both manual and automated injections, with the first two determinations representing the first analysis set and the second two determinations representing the second analysis set. This protocol was used to evaluate if a precision effect existed between taking the first determination from each analysis set (i.e., single determination) versus taking the average of the two determinations from each analysis set, as well as determining if there was a precision effect between manual and automated injections. The repeatability and reproducibility statements determined by the statistician reflect the corresponding precision values associated with testing conditions identified. It should be noted that the precision statements determined for the gasoline and RFG sample types in the 1999 ILS were poorer than expected relative to the precision statements determined for the distillates, basestocks, and lubricating oils as well as relative to the previously published method version precision statements (which were based on the analysis of just three pure compounds (benzene, toluene, and xylene) analyzed by 3 labs in duplicate). The poorer than expected precision statements for the gasoline and RFG sample types are likely due to the volatile nature of these materials, even though the ILS participants were provided instructions for how to properly handle these materials to minimize or prevent sample losses. The subcommittee responsible for the method is planning to conduct a subsequent ILS for gasoline and RFG sample types with additional scrutiny paid to sample handling issues as a means to try and improve the precision statements for these materials.

NOTE 7 - Four (4) of the samples analyzed in the ILS indicated in Note 6 were ASTM Interlaboratory Crosscheck samples (that is, Gasoline–MG9808 and MG9812, RFG–RFG9807, and RFG9809). The robust mean of the total vapor pressures reported by Test Method D5191 for these samples ranged from a low of 7.77 psi (MG9808) to a high of 13.40 psi (RFG9809). This corresponds to an approximate total vapor pressure range of 54 to 92 kPa.

15.2 Bias - After suggestions of its existence from literature, a study has been performed which has confirmed the presence of a bias between known density values for reference materials and from values determined according to this test method on the same reference materials. The matrix for this bias study comprised 15 participants, each analyzing four reference oils with certified density values, established by the Netherlands Meet Instituut (NMI), by pyknometry, covering densities in the range of 747 to 927 kg/m3 at 20°C, with viscosities between 1 and 5000 mPa.s (also at 20°C). This study is documented in ASTM Research Report D02-1387. Method users should, therefore, be aware that results obtained by this test method can be biased by as much as 0.6 kg/m3 (0.0006 g/mL).

NOTE 8 - Newer instrumentation exists which purports to correct density results due to the influence of viscosity. However, the responsible ASTM Technical Committee has not yet performed a new interlaboratory study to confirm the elimination of the bias described in ASTM Research Report D02-1387.

16. Keywords

16.1 API Gravity; density; digital density analyzer; petroleum distillates; petroleum products; relative density