10. Procedure

10.1 Weigh a clean test panel to the nearest 0.1 g, and record as W1, and then, using the metal jig (as shown in Fig. 2), use a spatula to spread approximately a 0.8 +/- 0.005-mm (1/32 -in.) thick film of grease. Clean off any grease beyond the raised section of the panel. Reweigh and record as W2.

10.2 Add an adequate amount of tap water to the reservoir and to cover the heater and adjust the water temperature to 38 +/- 0.5°C (100 +/- 1°F). When the water temperature in the reservoir reaches 38 +/- 0.5°C (100 +/- 1°F), circulate 2 to 3 min to attain temperature equilibrium before spraying the panel. Adjust pump pressure to 276 +/- 7 kPa (40 +/- 1 psi) using the bypass valve. The bypass valve must be ahead of the gauge, not between the gauge and nozzle. Shut off the motor.

10.3 Insert the panel, making sure the panel is level and centered below the spray nozzle. Start the motor and spray the water on the panel for 5 min +/- 15 s.

10.4 Shut off the motor to stop the spray, and remove the panel. Remove the excess grease outside the raised section of panel (area BC, Fig. 1) and along the sides and bottom of the panel. Place the panel in a horizontal position in an oven for 1 h +/- 5 min at 66 +/- 1°C (150 +/- 2°F).

10.5 Remove the panel from the oven, and allow to cool. Reweigh the panel, and record as W3.

11. Calculation

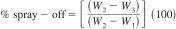

11.1 Calculate the percent spray-off as follows:

where:

W1 = initial mass of clean panel,

W2 = panel plus grease, before spraying, and

W3 = panel plus grease, after spraying.