9. Procedure

9.1 The precision of this test method can be affected by water droplets adhering to surfaces in the apparatus and therefore not settling into the water trap to be measured. To minimize the problem, all apparatus must be chemically cleaned at least daily to remove surface films and debris which hinder free drainage of water in the test apparatus. More frequent cleaning is recommended if the nature of the samples being run causes persistent contamination.

9.2 To determine water on a volume basis, proceed as indicated in 7.1.2.3. Add sufficient xylene to the flask to make the total xylene volume 400 mL.

9.2.1 To determine water on a mass basis, proceed as indicated in 7.1.2.4. Add sufficient xylene to the flask to make the total xylene volume 400 mL.

9.2.2 A magnetic stirrer is the most effective device to reduce bumping. Glass beads or other boiling aids, although less effective, have been found to be useful.

9.3 Assemble the apparatus as shown in Fig. 1, making sure all connections are vapor and liquid-tight. It is recommended that glass joints not be greased. Insert a drying tube containing an indicating desiccant into the end of the condenser to prevent condensation of atmospheric moisture inside the condenser. Circulate water, between 20 and 25°C, through the condenser jacket.

9.4 Apply heat to the flask. The type of crude oil being evaluated can significantly alter the boiling characteristics of the crude-solvent mixture. Heat should be applied slowly during the initial stages of the distillation (approximately 1/2 to 1 h) to prevent bumping and possible loss of water from the system. (Condensate shall not proceed higher than three quarters of the distance up the condenser inner tube (Point A in Fig. 1).) To facilitate condenser wash-down, the condensate should be held as close as possible to the condenser outlet. After the initial heating, adjust the rate of boiling so that the condensate proceeds no more than three quarters of the distance up the condenser inner tube. Distillate should discharge into the trap at the rate of approximately 2 to 5 drops per second. Continue distillation until no water is visible in any part of the apparatus, except in the trap, and the volume of water in the trap remains constant for at least 5 min. If there is a persistent accumulation of water droplets in the condenser inner tube, flush with xylene. (A jet spray washing tube, see Fig. 2, or equivalent device is recommended.) The addition of an oil-soluble emulsion breaker at a concentration of 1000 ppm to the xylene wash helps dislodge the clinging water drops. After flushing, redistill for at least 5 min (the heat must be shut off at least 15 min prior to wash-down to prevent bumping). After wash-down, apply heat slowly to prevent bumping. Repeat this procedure until no water is visible in the condenser and the volume of water in the trap remains constant for at least 5 min. If this procedure does not dislodge the water, use the TFE-fluorocarbon scraper, pick shown in Fig. 2, or equivalent device to cause the water to run into the trap.

9.5 When the carryover of water is complete, allow the trap and contents to cool to 20°C. Dislodge any drops of water adhering to the sides of the trap with the TFE-fluorocarbon scraper or pick and transfer them to the water layer. Read the volume of the water in the trap. The trap is graduated in 0.05-mL increments, but the volume is estimated to the nearest 0.025 mL.

10. Calculation

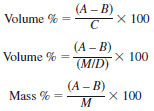

10.1 Calculate the water in the sample as follows:

where:

A = mL of water in trap,

B = mL of solvent blank,

C = mL of test sample,

M = g of test sample, and

D = density of sample, g/mL.

Volatile water-soluble material, if present, may be measured as water.