8. Calibration

8.1 Calibrate both the trap and the entire assembly prior to initial use and after any equipment changes as indicated in 8.1.1-8.1.3. Additionally, calibrate both the trap and the entire assembly periodically, at a frequency not to exceed yearly.

8.1.1 Verify the accuracy of the graduation marks on the trap by adding 0.05-mL increments of distilled water, at 20°C, from a 5-mL microburet or a precision micro-pipet readable to the nearest 0.01 mL. If there is a deviation of more than 0.050 mL between the water added and water observed, reject the trap or recalibrate.

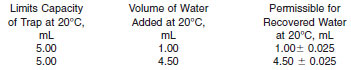

8.1.2 Also calibrate the entire apparatus. Put 400 mL of dry (0.02 % water maximum) xylene in the apparatus and test in accordance with Section 9. When complete, discard the contents of the trap and add 1.00 +/- 0.01 mL of distilled water from the buret or micro-pipet, at 20°C, directly to the distillation flask and test in accordance with Section 9. Repeat 8.1.2 and add 4.50 +/- 0.01 mL directly to the flask. The assembly of the apparatus is satisfactory only if trap readings are within the tolerances specified here:

8.1.3 A reading outside the limits suggests malfunctioning due to vapor leaks, too rapid boiling, inaccuracies in graduations of the trap, or ingress of extraneous moisture. These malfunctions must be eliminated before repeating 8.1.2.