5. Apparatus

5.1 The preferred apparatus, shown in Fig. 1, consists of a glass distillation flask, a condenser, a graduated glass trap, and a heater. Other types of distillation apparatus are specified in Specification E 123. Any of these apparatus will be acceptable for this test method provided it can be demonstrated that they operate within the precision established with the preferred apparatus.

5.1.1 Distillation Flask - A 1000-mL round-bottom, glass, distillation flask fitted with a 24/40 female taper joint shall be used. This flask receives a 5-mL calibrated, graduated water trap with 0.05-mL graduations. The trap will be fitted with a 400-mm Liebig condenser. A drying tube filled with desiccant (to prevent entrance of atmospheric moisture) is placed on top of the condenser.

5.1.2 Heater - Any suitable gas or electric heater that can uniformly distribute heat to the entire lower half of the flask may be used. An electric heating mantle is preferred for safety reasons.

5.1.3 The apparatus used in this test will be accepted when satisfactory results are obtained by the calibration technique described in Section 8.

6. Solvent

6.1 Xylene - reagent grade (Warning - Extremely flammable. Vapor harmful. See Annex A1.) A solvent blank will be established by placing 400 mL of solvent in the distillation apparatus and testing as outlined in Section 9. The blank will be determined to the nearest 0.025 mL and used to correct the volume of water in the trap as in Section 10.

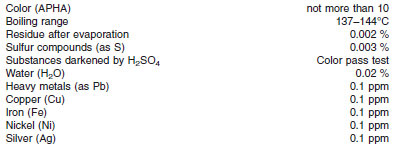

6.2 The xylene used in this procedure is generally a mixture of ortho, meta, and para isomers and may contain some ethyl benzene. The typical characteristics for this reagent are:

7. Sampling, Test Samples, and Test Units

7.1 Sampling is defined as all steps required to obtain an aliquot of the contents of any pipe, tank, or other system and to place the sample into the laboratory test container.

7.1.1 Laboratory Sample - Only representative samples obtained as specified in Practice D4057 (API MPMS Chapter 8.1) and Practice D4177 (API MPMS Chapter 8.2) shall be used for this test method.

7.1.2 Preparation of Test Samples - The following sample handling procedure shall apply in addition to those covered in 7.1.1.

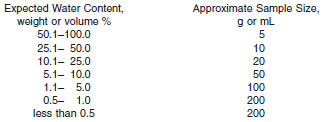

7.1.2.1 The sample size shall be selected as indicated below based on the expected water content of the sample:

7.1.2.2 If there is any doubt about the uniformity of the mixed sample, determinations should be made on at least three test portions and the average result reported as the water content.

7.1.2.3 To determine water on a volume basis, measure mobile liquids in a 5, 10, 20, 50, 100, or 200-mL calibrated, graduated cylinder (NBS Class A) depending on the sample size indicated in 7.1.2.1. Take care to pour the sample slowly into the graduated cylinder to avoid entrapment of air and to adjust the level as closely as possible to the appropriate graduation. Carefully pour the contents of the cylinder into the distillation flask and rinse the cylinder five times with portions of xylene equivalent to one-fifth of the capacity of the graduated cylinder and add the rinsings to the flask. Drain the cylinder thoroughly to ensure complete sample transfer.

7.1.2.4 To determine water on a mass basis, weigh a test portion of sample in accordance with 7.1.2.1, pouring the sample directly into the distillation flask. If a transfer vessel (beaker or cylinder) must be used, rinse it with at least five portions of xylene and add the rinsings to the flask.