8. Conversion of Calcium, Barium, Magnesium, or Ammonium Sulfonate to Sodium Sulfonate

8.1 Conversion ofCalcium, Barium, Magnesium or Ammonium Sulfonate to Sulfonic Acid:

8.1.1 Transfer approximately 10 g of sample, weighed to the nearest 0.001 g into a 250-mL Erlenmeyer flask, designating this weight as A. Add 50 mL of ethyl ether and stir to dissolve the sample. Add 100 mL of dilute HCl (1 + 1) and swirl to mix thoroughly until reaction is complete. In analyzing barium sulfonate products if barium chloride crystallizes out, add sufficient water to redissolve.

8.1.2 Quantitatively transfer the mixture to a 500-mL separatory funnel. Shake well, let settle, and draw the aqueous acid layer into a 250-mL separatory funnel. Extract the aqueous acid layer in the 250-mL separatory funnel with three 50-mL portions of ethyl ether, using the ethyl ether washes to rinse the Erlenmeyer flask first. Combine all the ethyl ether extracts in the 500-mL separatory funnel and wash with 50 mL of dilute HCl (1 + 3). Combine all the aqueous acid layers and reextract them with 50 mL of ethyl ether.

8.2 Conversion ofSulfonic Acid to Sodium Sulfonate:

8.2.1 Collect all of the ether washes in the 500-mL separatory funnel and shake with successive 50-mL portions of Na2SO4 solution containing 2 to 3 drops of methyl orange indicator until a washing does not appear pink. Discard the salt washes.

8.2.2 Drain off as much of the aqueous layer as possible from the washed ether solution. Lay the separatory funnel on its side and introduce about 10 g of anhydrous Na2SO4. Stopper the funnel, making sure that the funnel mouth is free of Na2SO4 crystals and shake the mixture vigorously for 3 to 4 min, to remove the last traces of water, venting the funnel frequently. Place a 250-mL Erlenmeyer flask on a steam bath and filter the ether solution through a small plug of cotton, placed in the vortex of a filter funnel, into the Erlenmeyer flask, keeping approximately 50 mL of solution in the Erlenmeyer flask while evaporating. Rinse the funnel and filter with 50 mL of ethyl ether, adding the rinsing to the main ether solution. Evaporate the ethyl ether until approximately 10 mL of solution remains. Add 50 mL of 99 mass % isopropyl alcohol, several drops of phenolphthalein indicator solution, and titrate with 0.1 mol/L standard NaOH solution to the red color change. Place the flask on a steam bath and evaporate to dryness. Dissolve the sodium sulfonate and oil residue in chloroform; transfer quantitatively into a 100-mL volumetric flask, adjust to volume, and proceed directly with Section 10. The solution may turn acidic on standing in the laboratory. Should this occur, add sufficient 0.1 N NaOH solution to the aliquot taken until the solution is pink.

9. Preparation of the Column

9.1 With the stopcock closed, pour 80 to 100 mL of chloroform into the column, and push a wad of cotton to the bottom with a rod (Note 1). Compress the cotton enough to hold back the silica gel but not enough to impede the flow of solvent.

NOTE 1 - A coarse-fritted disk made of borosilicate glass can be used in place of the cotton wad.

9.2 Pour 15 +/- 1 g of silica gel into the column containing the chloroform. The column must be free of air bubbles to avoid channeling. Start the flow of chloroform by opening the stopcock. When the liquid level is within 13 mm (1/2 in.) of the surface of the gel, close the stopcock. Never allow the liquid level to fall below the surface of the silica gel.

10. Separation of Mineral Oil and Sodium Sulfonate

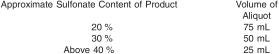

10.1 Adsorption of the Sample - Transfer a sufficient quantity of the chloroform solution of sodium sulfonate and mineral oil to provide approximately 1.25 g of Na2SO4 (8.2.2) onto the column, being careful to prevent channeling. Designate the volume as B. Use the following information as a guide in selecting the appropriate volume of sample:

10.1.1 For Sodium Sulfonate Products - Transfer approximately 2 g of sample, weighed to the nearest 0.001 g, into a 100-mL beaker, designating this weight as C. Add 10 to 25 mL ofchloroform and stir to dissolve the sample. Pour the solution onto the column, being careful to prevent channeling. Rinse the beaker several times with small portions ofchloroform and add the rinses to the column.

10.2 Elution ofthe Mineral Oil - Tare a 250-mL beaker, to the nearest 0.0001 g and place it under the column. Open the stopcock and adjust the flow rate to between 1 and 5 drops per second. Maintain the flow rate throughout the elution of the oil and sulfonate.

10.2.1 When the liquid level is within 13 mm (1/2 in.) of the surface of the gel, rinse the sides of the column with 10 mL of chloroform. When the liquid level is again within 13 mm (1/2 in.) of the surface of the gel, add 200 mL of chloroform.

10.2.2 If a column with a detachable reservoir is used, attach the reservoir at this point.

10.2.3 When the receiving beaker is about half full, remove it and place a clean, untared 250-mL beaker under the column to continue the elution. Place the tared beaker on the steam bath and gently evaporate the chloroform by blowing filtered air over the liquid surface. When the liquid level in the column is within 13 mm (1/2 in.) of the surface of the gel, rinse the sides of the column with 10 mL of ethyl alcohol. When the liquid level is again within 13 mm (1/2 in.) of the surface of the gel, repeat the rinse. The adsorbed sulfonate is always clearly visible and is sufficiently high in the column to prevent elution of sulfonate at this stage. Close the stopcock and quantitatively transfer the contents of the untared beaker to the tared beaker on the steam bath, by the use of chloroform.

10.3 Elution of Sulfonate - Tare a second 250-mL beaker to the nearest 0.0001 g and place it under the column. Add 230 mL of ethyl alcohol to the reservoir, open the stopcock and adjust the flow rate as described in 10.2.1 (Note 2). When the receiving beaker is about half full, remove it and place a clean, untared 250-mL beaker under the column. Place the tared beaker on the steam bath and evaporate gently, blowing filtered air over the liquid surface. When the liquid level in the column is within 13 mm (1/2 in.) of the surface of the gel, close the stopcock and quantitatively transfer the contents of the untared beaker to the second tared beaker on the steam bath, by the use of ethyl alcohol.

NOTE 2 - The flow rate may be maintained by applying compressed air if necessary.

10.4 Determination of Oil - Evaporate the chloroform solution from 10.2.2 until all but a few millilitres of chloroform have been evaporated. Remove the beaker from the steam bath and cool to room temperature. Place the beaker in a vacuum desiccator with a vacuum of 559 to 635 mm (22 to 25 in.) of mercury at room temperature. When the chloroform appears to have evaporated, remove the beaker and weigh. Return the beaker to the vacuum desiccator with a vacuum of 550 to 635 mm Hg (22 to 25 in.) for 30 min, remove, and weigh again. Repeat the drying and weighing until two successive weights are obtained that do not differ by more than 0.001 g. Designate the weight of the oil residue as D.

10.4.1 Some special petroleum sulfonate products may contain a light distillate as the diluent instead of mineral oil. In such cases, it is not possible to attain constant weight and the oil content determination must be disregarded.

10.5 Determination of Sulfonate - Evaporate the alcohol solution from 10.3 to dryness. Heat the beaker for 30 min in a vacuum oven at 100°C (212°F) and 550 to 635 mm Hg (22 to 25 in.) vacuum. Remove the beaker, cool, and weigh. Repeat the drying and weighing until two successive weights are obtained that do not differ by more than 0.001 g. Designate the mass of the sulfonate residue as E.

10.6 Blank Determination - Make a blank determination on a similar silica gel column, using the same lot of silica gel and reagents that are used in the analysis. Use the same procedure and quantities of reagents described in Section 7, but omit the sample. Determine the weights of the chloroform and alcohol residues as described in 10.4 and 10.5. Designate these weights as F and G, respectively. Repeat the blank determination whenever new lots of silica gel or reagents are used.

11. Average Equivalent Weight of Sodium Sulfonate

11.1 Dissolve the sulfonate residue (10.5) in 25 mL of chloroform, filter, if cloudy, through a slow-filtering, ashless, gravimetric paper and transfer the solution quantitatively into a tared, ignited, 100-mL platinum dish. Rinse the beaker, which contained the sulfonate residue with 25 mL of chloroform, adding the washings to the platinum dish, through the filter, if used. Evaporate to dryness on a steam bath. Dry to constant weight H in a vacuum oven at 100°C (212°F) and 559 to 635 mm Hg (22 to 25 in.) vacuum.

11.2 Carefully heat the dish over a small flame until the contents ignite and burn (Note 3). Place the dish on a hot plate and allow the contents to burn gently. Cool, add 3 or 4 drops of concentrated H2SO4 (relative density 1.84) and heat gently over a small flame until fuming ceases, taking care not to heat strongly enough to cause spattering. Then ignite over a burner, never allowing the dish to become hotter than a dull red, until all carbon has disappeared. Cool, add 3 or 4 drops of concentrated H2SO4, and fume off the acid as before, taking care to avoid spattering. When fuming ceases, heat in a muffle furnace at 800 to 1000°C (1500 to 1800°F) to constant weight. Cool in a desiccator prior to weighing. Designate this weight as I.

NOTE 3 - Ignition of sample and subsequent fuming with H2SO4 should be conducted in a suitable hood. Wear protective goggles during fuming of H2SO4.

12. Basicity or Acidity (Sodium Sulfonate Products)

12.1 The basicity of a sodium sulfonate product is determined by weighing 10 g of the sample (Note 4) to the nearest 0.01 g into a tared 250-mLbeaker, designating the sample mass as X. Add 100 mL of isopropyl alcohol (50 %) and stir to dissolve the sodium sulfonate and disperse the oil; warm, if necessary, to hasten the process. Add a few drops of phenolphthalein indicator solution. If the solution is pink, titrate with 0.1 mol/L H 2 SO 4 to the disappearance of the pink color. If the solution is colorless, titrate with 0.1 mol/L NaOH solution to the first persistent faint pink color (Note 5). Designate the volume of the reagent used as Y and its normality as Z.

NOTE 4 - The weight of sample taken for analysis should contain approximately 5 g of pure sodium sulfonate.

NOTE 5 - The basicity determined by the foregoing procedure includes that due to free NaOH and to the conversion of Na2CO3 to NaHCO3. If the alkalinity is due to NaOH and Na2CO3 only, and a more accurate measure of free NaOH is required, the method of Treadwell and Hall may be used.

13. Inorganic Salts (Sodium Sulfonate Products)

13.1 Weigh 3 g of sample to the nearest 0.5 mg in a tared ignited platinum crucible, designating the weight as AA. Carefully heat the dish over a small flame until the contents ignite and burn. Place the dish on a hot plate, and allow the contents to burn gently. Cool, add 3 or 4 drops of concentrated H2SO4, and heat gently over a flame until fuming ceases, taking care not to heat strongly enough to cause spattering (Note 3). Then ignite over a burner, never allowing the dish to become hotter than a dull red, until all carbon has disappeared. Cool, add 3 or 4 drops ofconcentrated H2SO4, and fume off the acid as before, taking care to avoid spattering. When fuming ceases, heat in a muffle furnace at 800 to 1000°F (1500 to 1800°F) to constant weight. Designate this weight at BB. Cool in a desiccator prior to each weighing.

14. Water

14.1 Determine the water content of the sample by Test Method D95.

15. Relative Density

15.1 Fill the pycnometer with the sample, warming to 70 to 80°C (160 to 180°F). Hold the pycnometer at 70 to 80°C (160 to 180°F) until all air bubbles have risen to the top. Place in a bath at 25 +/- 0.2°C (77 +/- 0.3°F) for 2 h, adding more sample if necessary, so the pycnometer remains full. Remove excess product flush with top of the pycnometer by means of a spatula. Remove the pycnometer from the bath, wipe the sides of the neck with a cloth, moistened with alcohol; wipe thoroughly dry; put the cap into place; and weigh to the nearest 1 mg. Designate this mass as Ws.

16. Base Number

16.1 Determine the total base number by Test Method D2896.