10. Procedure

10.1 Leave the sample and reference standard in the conditioning block for at least 0.5 h to ensure they reach uniform temperature, that is room temperature, before measurements are made.

10.2 Read the following instructions in conjunction with the procedure provided in the manufacturer's handbook for analyzing samples. Specific steps may vary with instrument manufacturer and model. In cases where the manufacturer's instructions differ from the following steps, follow the manufacturer's instructions.

10.3 Take the reference standard and place it carefully in the coil. When fully entered the top of the test cell should be just above the cover of the spectrometer unit.

10.4 Check that the peaks on the oscilloscope are coincident and if this is not so, adjust the tuning until they are.

10.5 When the reference standard has been in the magnet unit for at least 3 s, push the reset button.

NOTE 4 - It is important that a delay of this magnitude be allowed before commencing measurement in order that the hydrogen nuclei are fully polarized in the magnetic field.

10.6 After a count time of 128 s the digital display will stop at its final value. Record the integrator counts and push the reset button again and record the second reading.

10.7 Weigh the cell and contents and record the total mass.

10.8 Replace the reference standard in the conditioning block and make similar duplicate readings on the sample to be tested.

NOTE 5 - Measurements will be altered by temperature variations in the sample and reference standard so these must be returned to the conditioning block when measurements are not being made.

NOTE 6 - The determined hydrogen content will be affected by any instrument drift, slight variations in temperature between the sample and reference standard and loss of sample or reference standard, or both, due to evaporation. Therefore when a series of results are to be determined, sample and reference standard should be measured, weighed and calculated as pairs. When the mass change of the reference standard is greater than 0.01 g between consecutive weighings, the cause of this should be investigated and corrected. Losses are usually due to poor fitting of the PTFE plug while gains will probably be due to contamination of the coil.

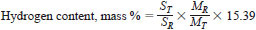

11. Calculation

11.1 For each sample and reference standard, subtract the mass of the test cell and PTFE plug from the total mass of the test cell determined in 10.7.

where:

ST = mean of integrator counts on sample under test,

SR = mean of integrator counts on reference standard,

MR = mass of reference sample, and

MT = mass of sample under test