8. Method A - Vacuum Extraction

8.1 Method A employs vacuum extraction to separate the gases from the oil. The evolved gases are compressed to atmospheric pressure and the total volume measured. The gases are then analyzed by gas chromatography.

9. Preparation of Apparatus

9.1 Check the apparatus carefully for vacuum tightness of all joints and stopcocks.

9.2 Measure the total volume of the extraction apparatus, VT, and the volume of the collection space, Vc, and calculate the ratio as the volumetric collection ratio:

where Vo = the volume of oil to be added.

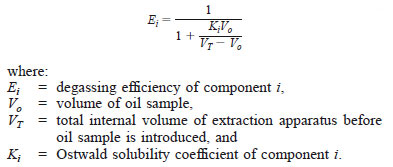

9.3 Calculate the degassing efficiencies for each individual component gas as follows:

where:

9.4 Determine the Ostwald solubility coefficients of fixed gases in accordance with Test Method D 2780.

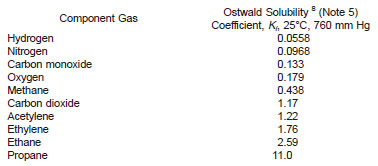

9.5 Ostwald solubility coefficients that have been determined for a number of gases in one specific electrical insulating oil at 25°C are shown as follows. Values for gases in other oils may be estimated by reference to Test Method D 2779.

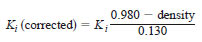

NOTE 5 - The Ostwald coefficient values shown in this table are correct only for the specific mineral oil having a density at 15.5°C of 0.855 g/cm3 used in the original determination. Ostwald coefficients for mineral oils of different density may be calculated as follows:

where, density = density of the oil of interest, g/cm3 at 15.5°C (60°F). This equation is derived from the equation in Test Method D 2779. Note especially that all of the Ostwald coefficients are changed by the same factor, meaning that though the absolute solubilities of each of the gases will change if a different oil is used, the ratio of the solubility of one gas to another gas will remain constant.

9.6 A procedure to check the extraction efficiency requires the use of prepared gas-in-oil standards of known concentration. The methods of preparation are outlined in Annex A1 and Annex A2.