ASTM D3606 Standard Test Method for Determination of Benzene and Toluene in Finished Motor and Aviation Gasoline by Gas Chromatography

11. Calibration and Standardization

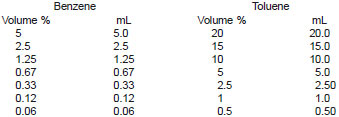

11.1 Standard Samples - Prepare seven standard samples covering the range 0 to 5 volume % benzene and 0 to 20 volume % toluene as follows: For each standard, measure the volume of benzene and of toluene listed below into a 100-mL volumetric flask. Dilute to volume with isooctane, with all components and glassware at ambient temperature.

11.2 Calibration Blends - Accurately measure 1.0 mL of MEK into a 25-mL volumetric flask, and fill to the mark with the first standard sample (11.1). Continue doing this until all blends have been prepared.

11.3 Chromatographic Analysis - Chromatograph each of the calibration blends using the conditions established in 10.4 using the following injection technique:

11.4 Injection of Sample:

11.4.1 Use of an automatic liquid sample injection system is highly recommended. If manual injections are to be made, the injection technique in 11.4.2 is necessary so that sharp symmetrical peaks will be obtained.

11.4.2 Flush the 5-µL microsyringe at least three times with the sample mixture and then fill with about 3µ L of the sample. (Avoid including any air bubbles in the syringe.) Slowly eject the sample until 2.0 µL remains in the syringe; wipe the needle with tissue and draw back the plunger to admit 1 to 2 µL of air into the syringe. Insert the needle of the syringe through the septum cap of the chromatograph and push until the barrel of the syringe is resting against the septum cap; then push the plunger to the hilt and remove the syringe immediately from the chromatograph.

11.5 Calibration - Measure the area of both aromatic peaks and of the internal standard peak as directed in 12.4. Calculate the ratio of the benzene peak area to the MEK peak area. Plot the concentration of benzene versus the ratio. Make the same calculation and plot for toluene. See Fig. 3 for an example. This must be done to ensure that the entire chromatographic system is operating properly and that the concentration of any one component has not exceeded the linear response range of any part of the system: column, detector, integrator, and other components. The calibration should be linear.

NOTE 12 - If the calibration has been shown to be linear, a least squares calculation may be performed to calculate a calibration factor. The precision statement in Section 15 was developed from data obtained from calibration plots and may not apply if calibration factors are used.