ASTM D3524 Standard Test Method for Diesel Fuel Diluent in Used Diesel Engine Oils by Gas Chromatography

5. Apparatus

5.1 Gas Chromatograph - Any gas chromatograph can be used that has the following performance characteristics:

5.1.1 Detector - Either a thermal conductivity or flame ionization detector can be used. The detector must have sufficient sensitivity to detect 1.0 % decane with a peak height of at least 10 % of full scale on the recorder under the conditions prescribed in this method, and without loss of resolution as defined in 7.1.3. The detector also must be capable of operating continuously at a temperature equivalent to the maximum column temperature employed, and it must be connected to the column so as to avoid any cold spots. Under the conditions described for the method, the drift should not be more than 1 % of full scale per hour.

5.1.2 Column Temperature Programmer - The chromatograph must be capable of program temperature operation over a range sufficient to establish a retention time of at least 1 min for the initial peak(s) and to elute the entire sample. The programming rate must be sufficiently reproducible to obtain retention time repeatability of 0.1 min for each component in the calibration mixture (6.4).

5.1.3 Sample Inlet System - The sample inlet system must be capable of operating continuously at a temperature equivalent to the maximum column temperature employed, or provide on-column injection with some means of programming the entire column, including point of sample introduction up to the maximum temperature required. The sample inlet system must be connected to the chromatographic column so as to avoid any cold spots.

5.2 Recorder - A recording potentiometer with a full-scale response time of 2 s or less must be used. If a manual method of area measurement, such as a planimeter, is employed, the chart speed must be at least 152 cm/h (60 in./h) to minimize errors in peak area measurements. This requirement is waived if a ball-and-disc integrator or an electronic integrator is employed.

5.3 Column - Any column and conditions may be used, provided, under the conditions of the test, separations are in order of boiling points and the column resolution, R, is at least 3 and not more than 5 (7.1.3). Since a stable baseline is an essential requirement of this method, matching dual columns are required to compensate for column bleed, which cannot be eliminated completely by conditioning alone.

5.4 Integrator - Means must be provided for determining the accumulated area under the chromatogram. This can be done manually by means of a polar planimeter. Mechanical means, such as the disc integrator, may be used also. However, best precision and automatic operation can be achieved with electronic integration.

5.5 Flow Controllers - Chromatographs using thermal conductivity detectors also must be equipped with constant-flow controllers capable of holding carrier gas flow constant to +/-1 % over the full operating temperature range.

5.6 Sample Device:

5.6.1 Micro Syringe - A micro syringe, usually 10 µL, is used for sample introduction.

5.6.2 Automatic sampling devices or other sampling means, such as indium encapsulation, may be used, provided the system can be operated at a temperature sufficiently high to vaporize completely hydrocarbons with an atmospheric boiling point of 538°C (1000°F), and the sampling system is connected to the chromatographic column so as to avoid any cold spots.

5.7 Vial, 15-mL, screw cap.

6. Reagent and Material

6.1 Liquid Phase for Columns - See Note 2.

NOTE 2 - The following materials have been used successfully as liquid phases:

Silicone Gum Rubber UC-W98

Silicone Gum Rubber GE-SE-30

Silicone Gum Rubber OV-1

Silicone Gum Rubber OV-101

6.2 Solid Support - Usually crushed fire brick or diatomaceous earth. Sieve size and support loading should be such as will give optimum resolution and analysis time. In general, support loadings of 3 to 10 % have been found most satisfactory.

6.3 Carrier Gas - Helium ( Warning - See Note 3.) or hydrogen (Warning - See Note 4) for use with thermal conductivity detectors; or nitrogen, (Warning - See Note 3.) helium, or argon for use with flame ionization detectors.

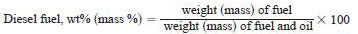

6.4 Calibration Mixtures - A minimum of three mixtures of diesel fuel and lubricating oil (Warning - See Note 5.) of a similar type to that being analyzed are prepared to cover the range from 0 to 12 weight% (mass%) diesel fuel, calculated as follows:

NOTE 3 - Warning: Argon, helium, and nitrogen are compressed gases under pressure.

NOTE 4 - Warning: Hydrogen is an extremely flammable gas under pressure.

NOTE 5 - Warning: Combustible liquid.

6.5 n-Decane, 99 % pure. (Warning - See Note 6.)

NOTE 6 - Warning: Combustible, vapor harmful.