3. Terminology Definitions

3.1 Type I Mineral Oil - an oil for apparatus where normal oxidation resistance is required. Some oils may require the addition of a suitable oxidation inhibitor to achieve this.

3.2 Type II Mineral Oil - an oil for apparatus where greater oxidation resistance is required. This is usually achieved with the addition of a suitable oxidation inhibitor.

NOTE 1 - During processing of inhibited mineral oil under vacuum and elevated temperatures, partial loss of inhibitor and volatile portions of mineral oil may occur. The common inhibitors, 2,6-ditertiary-butyl para-cresol and 2,6-ditertiary-butyl phenol, are more volatile than transformer oil. If processing conditions are too severe, oxidation stability of the oil may be decreased due to loss of inhibitor. The selectivity for removal of moisture and air in preference to loss of inhibitor and oil is improved by use of a low processing temperature.

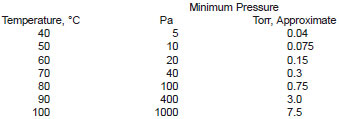

Conditions that have been found satisfactory for most inhibited mineral oil processing are:

If temperatures higher than those recommended for the operating pressure are used, the oil should be tested for inhibitor content and inhibitor added as necessary to return inhibitor content to its initial value. Attempts to dry apparatus containing appreciable amounts of free water may result in a significant loss of inhibitor even at the conditions recommended above.

3.3 additives - chemical substances that are added to mineral insulating oil to achieve required functional properties.

3.4 properties - those properties of the mineral insulating oil which are required for the design, manufacture, and operation of the apparatus. These properties are listed in Section 5.

4. Sampling and Testing

4.1 Take all oil samples in accordance with Test Methods D923.

4.2 Make each test in accordance with the latest revision of the ASTM test method specified in Section 5.

4.3 The oil shall meet the requirements of Section 5 at the unloading point.

NOTE 2 - Because of the different needs of the various users, items relating to packaging, labeling, and inspection are considered to be subject to buyer-seller agreement.

NOTE 3 - In addition to all other tests listed herein, it is sound engineering practice for the apparatus manufacturer to perform an evaluation of new types of insulating oils in insulation systems, prototype structures, or full-scale apparatus, or any combination thereof, to assure suitable service life.

4.4 Make known to the user the generic type and amount of any additive used, for assessing any potential detrimental reaction with other materials in contact with the oil.

5. Property Requirements

5.1 Mineral insulating oil conforming to this specification shall meet the property limits given in Table 1. The significance of these properties is discussed in Appendix X2.