ASTM D3455 standard test methods for compatibility of construction material with electrical insulating oil of petroleum origin

7. Procedure

7.1 With a pair of clean tongs remove the test specimen from the oil, observe the condition, and conduct any desired test on the material.

7.1.1 Typical tests on materials can include swelling or dimensional change, hardness, discoloration, brittleness, etc.

7.1.2 For comparative tests use the appropriate method.

7.2 The following tests on all oil specimens are suggested:

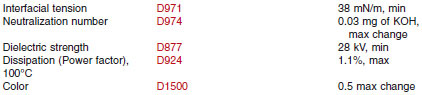

7.2.1 Interfacial Tension - Test Method D971.

7.2.2 Neutralization Number - Test Method D974.

7.2.3 Dielectric Strength - Test Method D877.

7.2.4 Dissipation (Power Factor) - Test Method D924.

7.2.5 Color - Test Method D1500.

8. Evaluation of Results

8.1 Evaluation of Physical Changes of the Material at Room Temperature - The changes in physical properties of the material being tested must be considered on the basis of the specific needs of the application.

8.2 Evaluation of Test Results on Insulating Oil:

8.2.1 The test results obtained on the oils containing the test specimens must be compared with those of the reference oil specimen to determine any differences.

8.2.2 The absence of any differences between the test specimen oil and the reference oil indicates that the test specimen oil was not affected by the material and that the material is worthy of further consideration or testing, or both.

8.2.3 A significant difference in any of the results as defined in 8.2.5 may indicate some compatibility problem and the material should be either further reviewed or rejected.

8.2.3.1 The magnitude of differences in properties between the reference oil and the test specimen oil that constitute a significant change should be established prior to testing, by agreement between the purchaser and the seller.

8.2.4 If the aged reference oil exceeds the limits in 8.2.5, the oil itself is suspect for one or more of the following reasons:

8.2.4.1 The oil does not meet the requirements for an approved insulating oil.

8.2.4.2 The oil has become contaminated.

8.2.4.3 The test aging temperature exceeded the prescribed limit (see 6.1).

8.2.5 The aged properties for the reference oil specimen should be as follows (Note 4):

NOTE 4 - The values are typical values for most of the mineral oils presently on the market.