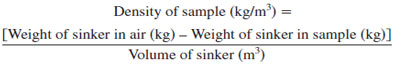

10.1 Density:

10.2 Target Density:

Initial density x 0.998

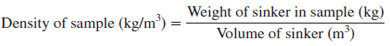

10.3 If the tare key of the balance is pressed while the sinker is being weighed in air so that the reading is zeroed, then the following may be used:

NOTE 14 - Some instruments automatically make the above calculations.

10.4 The volume of the sinker may be determined by weighing it in air, then in water. The difference in weight(kg) x 10–3 = volume in m3.

11. Reporting

11.1 Report the air release time, as recorded in 9.9, and the test temperature in °C.

12. Precision and Bias

NOTE 15 - The program was run by six laboratories, using five samples of unused steam turbine oils and base stocks with air used as the entrained gas. Five samples were tested at one temperature and four at another. Since some reports were incomplete, this resulted in 48 pairs of replicated data.

12.1 Precision - The precision of this test method as determined by statistical examination of interlaboratory results is as follows:

NOTE 16 - The precision statement was developed using 1.1.1 trichloroethane and chrome sulfuric acid in the cleaning procedure.

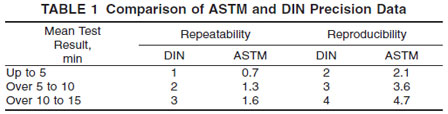

12.1.1 Repeatability - The difference between two test results, obtained by the same operator with the same apparatus under constant operating conditions on identical test material, would in the long run, in the normal and correct operation of the test method, exceed the following values only in one case in twenty:

0.5 times the square root of their mean

12.1.2 Reproducibility - The difference between two single and independent results obtained by different operators working in different laboratories on identical test material would, in the long run, in the normal and correct operation of the test method, exceed the following values only in one case in twenty:

1.3 times the square root of their mean

12.2 The closely related test method DIN51 381 reports precision in another format. For ready comparison, the above statement is shown in DIN terms in Table1.

12.3 Bias - The procedure in Test Method D3427 for measuring air release properties of petroleum oils has no bias because the value of the air bubble separation time is defined only in terms of this test method. There is no known bias relative to the DIN 51 381 method.

NOTE 17 - The above precision was determined only at test temperatures of 50°C and 82°C. A new interlaboratory test program is planned.13. Keywords

13.1 air entrainment; air release time; gear oil; hydraulic oil; turbine oil