5. Apparatus

5.1 Mixing Beaker, 5800 mL capacity, made of stainless steel, modified as shown in Annex A2.

5.2 Combination Agitator and Temperature Control Devcice.

5.3 Babcock Centrifuge Bottles - The 165-mm cream test bottle, with 5 mL-neck permitting oil concentration readings from 0 to 10 % is preferred. These bottles should be marked for filling to the 50–mL level which will normally be found close to the junction of body and neck. Sulfonation bottles may also be used.

5.4 Centrifuge, capable of whirling the Babcock bottles at sufficient speed to give a clean separation of oil and water under the test conditions. A centrifuge giving a relative centrifugal force (rcf) of 5009 at the bottle tips has been found to give good separations in 10 min.

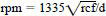

5.5 To calculate the rpm required to achieve the stated rcf, use the following formula:

where:

rcf = relative centrifugal force,

d = diameter of swing measured between tips of opposite tubes when in rotating position, mm, and

rpm = revolutions per minute.

5.6 Stop Watch, or similar timing device.

6. Reagents

6.1 Buffered Synthetic Hard Water, prepared in accordance with Annex A2.

6.2 Sulfuric Acid, 30 vol % in water. Lower acid concentrations may be used if clean separations are obtained.

NOTE 1 - Warning: Sulfuric acid is poison, corrosive, and a strong oxidizer.