5. Apparatus

5.1 Filter Stick and Assembly, consisting of a 10 mm diameter sintered glass filter stick of 10 µm to 15 µm maximum pore diameter as determined by the method in Appendix X1, provided with an air pressure inlet tube and delivery nozzle. It is provided with a ground-glass joint to fit a 25 mm by 170 mm test tube. The dimensions for a suitable filtration assembly are shown in Fig. 1.

NOTE 1 - A metallic filter stick may be employed if desired. A filter stick 3 made of stainless steel and having a 12.7 mm (0.50 in.) disk of 10 nm to 15 nm maximum pore diameter, as determined by Test Method E128, has been found to be satisfactory. The metallic apparatus is inserted into a 25 mm by 150 mm test tube and held in place by means of a cork.

5.2 Cooling Bath, consisting of an insulated box with 30 mm +/- 5 mm (1.2 in. +/- 0.2 in.) holes in the center to accommodate any desired number of test tubes. The bath may be filled with a suitable medium such as kerosine, and may be cooled by circulating a refrigerant through coils, or by using solid carbon dioxide. A suitable cooling bath to accommodate three test tubes is shown in Fig. 2.

5.3 Dropper Pipet, dispensing device capable of delivering 0.5 g +/- 0.05 g of molten wax.

5.4 Transfer Pipet, or equivalent volume dispensing device, capable of delivering 15 mL +/- 0.06 mL.

5.5 Air Pressure Regulator, designed to supply air to the filtration assembly (8.5) at sufficient pressure to give an even flow of filtrate. Either a conventional pressure-reducing valve or a mercury bubbler-type regulator has been found satisfactory. The latter type, illustrated in Fig. 3, consists of a 250 mL glass cylinder and a T-tube held in the cylinder by means of a rubber stopper grooved at the sides to permit the escape of excess air. The volume and pressure of the air supplied to the filtration assembly is regulated by the depth to which the T-tube is immersed in mercury at the bottom of the cylinder. Absorbent cotton placed in the space above the mercury prevents the loss of mercury by spattering. The air pressure regulator is connected to the filter stick and assembly by means of rubber tubing.

5.6 Temperature Measuring Devices:

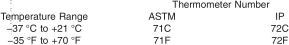

5.6.1 Thermometers, two, having a range as shown below and conforming to the requirements as prescribed in Specification E1 or in the specifications for IP Standard Thermometers. One thermometer is required for the cold bath and a second thermometer is required for the sample solution.

5.6.2 Temperature measuring devices other than those described in 5.6.1 are satisfactory for this test method, provided they exhibit the same temperature response as the equivalent mercury-in-glass thermometers.

5.7 Weighing Bottles, glass-stoppered, having a typical capacity of 15 mL to 25 mL.

5.8 Evaporation Assembly, consisting of an evaporating cabinet and connections, essentially as illustrated in Fig. 4, and capable of maintaining a temperature of 35 °C +/- 1 °C (95 °F +/- 2 °F) around the evaporation flasks. Construct the jets with an inside diameter of 4 mm +/- 0.2 mm for delivering a stream of clean, dry air vertically downward into the weighing bottle. Support each jet so that the tip is 15 mm +/- 5 mm above the surface of the liquid at the start of the evaporation. Supply purified air at the rate of 2 L/min to 3 L/min per jet. One way to purify the air is to pass it through a tube of approximately 1 cm bore packed loosely to a height of approximately 20 cm with absorbent cotton. Periodically check the cleanliness of the air by evaporating 4 mL of the solvent mixture described in 6.3 by the procedure specified in 8.5. When the residue does not exceed 0.1 mg, the evaporation equipment is operating satisfactorily.

NOTE 2 - Investigations by the European World Federation have indicated that improved precision may be achieved by individually calibrating each nozzle to deliver a flow rate of 2 L/min to 3 L/min.

5.9 Analytical Balance, capable of reproducing masses to 0.1 mg.

5.10 Wire Stirrer - A piece of stiff made of iron, stainless steel, or Nichrome wire of about No. 20 Bands (0.9 mm in diameter) or 16 swg. gage, 250 mm long. A 10 mm diameter loop is formed at each end, and the loop at the bottom end is bent so that the plane of the loop is perpendicular to the wire.

6. Solvent

6.1 Methyl Ethyl Ketone, conforming to the specifications of the Committee on Analytical Reagents of the American Chemical Society.

6.2 Toluene, conforming to the specifications of the Committee on Analytical Reagents of the American Chemical Society.

6.3 Solvent Mixture - Prepare a mixture of 50 % by volume methyl ethyl ketone and 50 % by volume toluene.

6.4 Store the solvent mixture over a suitable drying agent, such as anhydrous calcium sulfate (five mass percent of the solvent). Filter prior to use.

7. Sample

7.1 Obtain a representative portion by melting the entire sample and stirring thoroughly. This is necessary because the extractables may not be distributed uniformly throughout the solidified sample.