PROCEDURE A - USING TABLETS

9. Apparatus

9.1 Graduated Cylinder, glass-stoppered, 100 mL, with 1-mL graduations (two required).

9.2 Tablet Press - See 10.2.

10. Reagents and Materials

10.1 Acid Solution (12 volume %) - Add and mix slowly with caution 12 volumes of concentrated sulfuric acid (H2SO4, relative density 1.84) into 88 volumes of water. (Warning - See Note 4 and Note 5.)

NOTE 4 - Warning: Corrosive. Causes severe burns.

NOTE 5 - Precaution: Mixing sulfuric acid with water generates heat. Always add the acid to the water and add it slowly. Never add the water to the acid.

10.2 Potassium Periodate Tablet.6 (Warning - See Note 6.)

NOTE 6 - Warning: Toxic. Hazardous.

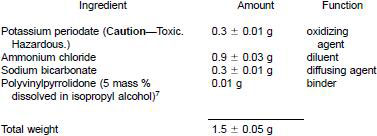

10.2.1 Composition of Tablet:

10.2.2 Preparation of Tablet - Bind chemicals into tablet form not to exceed 13 mm in diameter. The tablet should withstand reasonable handling and be readily soluble in the acid solution (Note 7). Store in amber glass bottles with a plastic cap at room temperature and out of direct rays of the sun. In this way the tablet will remain stable for at least five years.

NOTE 7 - Exercise care in the preparation of the tablets to assure that they are not so brittle that they will crumble in handling or not so compact that they will not readily dissolve in the acid solution.

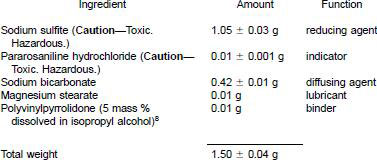

10.3 Sodium Sulfite/Pararosaniline Hydrochloride Tablet (Warning See Note 6.)

10.3.1 Composition of Tablet:

10.3.2 Preparation of Tablet - Mix and grind together the sodium sulfite, sodium bicarbonate, and the pararosaniline hydrochloride. Pass the mixture through a 180-µm (80-mesh) sieve, dampen with the polyvinylpyrrolidone in alcohol, and pass through a 425-µm (40-mesh) sieve. Dry for 4 h at 380°C and overnight at room temperature. Pass through a 500-µm (30-mesh) sieve. Sprinkle with magnesium stearate and mix. Press into tablet form not to exceed 13 mm in diameter. The tablet should withstand reasonable handling and be readily soluble in the acid solution (Note 7). Store in an amber glass bottle with plastic cap at room temperature or lower and out of the direct rays of the sun. In this way, the tablets will remain stable for at least five years.

10.4 Toluene - (Warning - See Note 8.)

NOTE 8 - Warning: Toxic. Flammable.

11. Preparation of Apparatus

11.1 Rinse the cylinder first with toluene to remove the used oil/toluene mixture and then with hot water. Dry.

11.2 Caution - Do not use soaps or detergents for cleaning because they can leave residues that can interfere with the separation of the aqueous layer.

12. Procedure

12.1 Bring the sample to room temperature and shake well to ensure even distribution of any glycol throughout the sample (Section 8). Use only reagents at room temperature (above 18°C).

12.2 Pour toluene into a 100-mL glass-stoppered cylinder to the 80-mL mark. Add the well-mixed oil sample to the 100-mL mark. Stopper the cylinder and mix well.

12.3 Pour acid solution into another 100-mL glass-stoppered cylinder to the 60-mL mark. Drop a potassium periodate tablet into the acid solution and allow it to dissolve. Bring to the 80-mL mark with the well-mixed toluene/oil mixture from the other cylinder. Shake vigorously for 1 min, being careful to avoid leakage of liquid from around the stopper. Remove the stopper and let the cylinder stand for 10 min.

12.4 Drop in a sulfite/pararosaniline tablet and wait for 30 min. Upon addition of the tablet, effervescence commences, and a deep brownish color develops in the aqueous layer in about 1 min and then disappears.

12.5 After the disappearance of the brown color, observe the formation of color in the aqueous layer.

13. Observations and Interpretations

13.1 Regard a yellow or pale green coloration that persists for at least 30 min as a negative test result.

13.2 Regard a pale, dirty green color that gradually turns to purple in 30 min as a trace test result. This trace quantity is in the range of 100 to 300 mg/kg.

13.3 Regard a purple color, which may intensify upon standing for 30 min, as a positive test result. When the purple color appears within a few minutes, more than 1 % glycol is present.

13.4 When the test result is positive or trace, and sugar or sugar-containing materials are suspected of being present, instead of performing the test directly on the toluene/oil mixture (12.2), do a water test (Test Method D95 first on the 100 mL of this mixture, transfer the condensed trap contents to the acid/periodate solution in the glass-stoppered cylinder (12.3), and carry out the rest of the antifreeze test. Discard the oil/solvent residue from the water test that would contain any sugar. The presence or absence of interfering compounds from manufacture can be confirmed by carrying out the test on new or preferably on the used oil known not to be contaminated by glycol-base antifreeze as the concentration of these compounds tends to diminish in use. Allow for such interference when reporting results.

13.5 When a positive test result is obtained, perform the test on the same oil, unused, or the same oil, used and known to contain no antifreeze. A difference in the color formation, especially a bluish tint, between the blank and the used oil indicates a positive result. A positive result cannot be confirmed if there is no difference between the color formation of the blank and used oil.

13.6 A light red (13.2) or a deep red (13.3) may also be an indication of a positive test. However this can be confirmed by testing the color formation in the same oil, unused, or on the same used oil which is known to contain no antifreeze. A difference in the color formation, especially a bluish tint, between the blank and the used oil indicates a positive result. A positive result cannot be confirmed if there is no difference between the color formation of the blank and used oil.

NOTE 9 - The Gly-Tek test kit is provided with a color chart. This chart uses only varying intensities of the purple color.