10. Precision and Bias (Test Method A)

10.1 The precision of this test method is not known to have been obtained in accordance with currently accepted guidelines (for example, in Committee D02 Research Report RR:D02-1007).

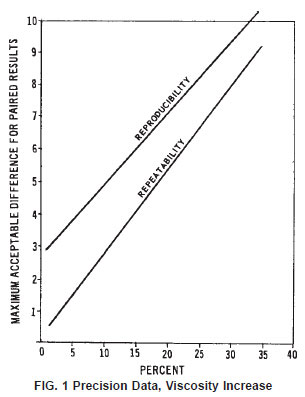

10.2 Viscosity Increase:

10.2.1 Repeatability - Duplicate results by the same operator shall be considered suspect if they differ by more than the maximum acceptable difference for repeatability as shown in Fig. 1.

10.2.2 Reproducibility - The results submitted by each of two laboratories shall be considered suspect if they differ by more than the maximum acceptable difference for reproducibility as shown in Fig. 1.

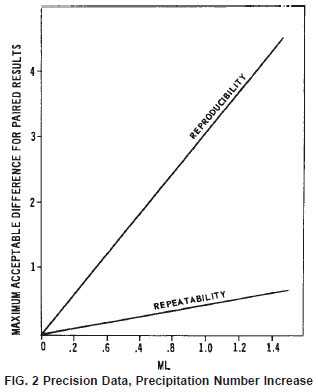

10.3 Precipitation Number, Increase:

10.3.1 Repeatability - Duplicate results by the same operator shall be considered suspect if they differ by more than the maximum acceptable difference for repeatability as shown in Fig. 2.

10.3.2 Reproducibility - The results submitted by each of two laboratories shall be considered suspect if they differ by more than the maximum acceptable difference for reproducibility as shown in Fig. 2.

10.4 Bias - The procedure in this test method has no bias because the value of these changes can only be defined in terms of a test method.

11. Precision and Bias (Test Method B)

11.1 Viscosity Increase:

11.1.1 Repeatability - The difference between successive results obtained by the same operator with the same apparatus under constant operating conditions on identical test materials would, in the long run, in the normal and correct operation of this test method, exceed the flowing values only in one in twenty:

Repeatability = 0.30X

where:

X = the mean value.

11.1.2 Reproducibility - The difference between two single and independent results obtained by different operators in different laboratories on identical material would, in the long run, exceed the following values only in one case in twenty:

Reproducibility = 1.1X

where:

X = the mean value.

NOTE 5 - This precision statement was prepared with data on six oils tested by six cooperators. The oils covered values of 0-20 % viscosity increase.

11.2 The precision for the precipitation number was not determined.

11.3 Bias - The procedure in this test method has no bias, because the value of these changes can only be defined in terms of a test method.

12. Keywords

12.1 extreme pressure gear oils; oxidation testing-petroleum; stability-oxidation; stability-thermal

SUMMARY OF CHANGES

Subcommittee D02.09 has identified the location of selected changes to this standard since the last issue (D2893–03) that may impact the use of this standard.

(1) Added Test Method D943 to the Referenced Documents

(2) Clarified that stirring device is used only for liquid baths in 5.1.

(3) Added Note 4.