6. Procedure

6.1 Cleaning and Flushing of Test System - Proper cleaning and flushing of entire test system is extremely important in order to prevent cross-contamination of test fluids.

6.1.1 Open all drain valves and the petcocks at all low areas to permit removal of the used test fluid.

6.1.2 Remove the used pump cartridge, if not already done.

6.1.3 Clean the pump housing with an appropriate solvent (use Stoddard Solvent (Warning - see Note 7) for petroleum and synthetic fluids; hot water for water glycol and other water based fluids).

NOTE 7 - Warning: Combustible. Vapor harmful.

6.1.4 Visually examine the pump head and the interior of the pump body. Replace if evidence of deterioration is observed.

6.1.5 Replace the pump drive shaft and bearings after every 5 runs (or sooner if high weight loss, vibration, cavitation or visual deterioration are encountered). The seals must be changed after every run.

6.1.6 Insert a good used pump cartridge into the pump housing to circulate the flushing fluid.

6.1.7 Check pump alignment.

6.1.8 Remove the used filter element, clean the filter housing, and install a new filter element.

6.1.9 Remove, clean, and re-install the 60 mesh screen in the reservoir outlet.

6.1.10 Close the reservoir outlet valve and pour 5.7 to 7.6 L (1.5 to 2 gal) of the appropriate cleaning solvent (4.1.3) into the reservoir.

6.1.11 Close all drain valves and petcocks and open the reservoir outlet valve to allow the flushing fluid to fill the pump and the lower lines of the system.

NOTE 8 - If a 56.8 L (15 gal) system is used, system flushing is conducted with 18.9 to 28.4 L (5 to 7.5 gal) of the appropriate cleaning solvent.

6.1.12 Reduce the setting of the pressure control valve if not already done.

6.1.13 Jog the pump drive motor ON and OFF switches to remove the air from the test system. Continue until the fluid returning to the reservoir is visually free of air.

NOTE 9 - If fluid cannot be visually observed in the reservoir, the lack of pump noise is an acceptable indication that the fluid is suitably deaerated.

6.1.14 Circulate the flushing fluid through the system for 1/2 h at 1200 r/min (use a pressure of 1.38 MPa (200 psi) when using water or 6.89 MPa (1000 psi) when using Stoddard Solvent). Maintain a temperature between 37.8 and 48.9°C (100 and 120°F).

NOTE 10 - One flush of this petroleum solvent is usually sufficient to clean a system in which an oil was run. Other solvents can be used when oxidized oil has coated the reservoir and lines. Repeat the flush if the first flush is cloudy or opaque. In some cases, hot water can be suitable for flushing the system.

6.1.15 Drain the flushing fluid.

6.1.16 Remove the filter element, clean the filter housing, and re-install the same filter element.

6.1.17 Repeat 6.1.10 through 6.1.13 using 5.7 to 7.6 L (1.5 to 2 gal) of new test fluid with the pressure increased to 6.89 MPa (1000 psi).

NOTE 11 - If a 56.8 L (15 gal) system is used, this flush is conducted with 18.9 to 28.4 L (5 to 7.5 gal) of new test fluid.

6.1.18 Completely drain the test system of all fluid.

6.1.19 Remove, clean, and re-install the 60 mesh screen in the reservoir outlet.

6.1.20 Remove the filter element, clean the filter housing, and install a new filter element.

6.1.21 Remove the flushing cartridge from the pump housing.

6.1.22 Close the reservoir outlet valve.

6.1.23 Put 11.4 L (3 gal) of new test fluid into reservoir.

6.2 Preparation of New Test Cartridge:

6.2.1 Inspect all cartridge components for manufacturing or material irregularities. A completely new pump cartridge must be used for each test. Do not re-use any cartridge components.

6.2.2 Remove the sharp edges and burrs from all steel cartridge parts with an oil stone.

6.2.3 Inspect the rotor for cracks and make sure the rotation arrows on it and the bushings are correct.

NOTE 12 - While not required, some laboratories lap the terminal holes at the base of the vane slots in the rotor in an attempt to minimize the possibility of rotor segment breakage. To do this, each hole is lapped for several minutes using a 3/32 in. (2.38 mm) diameter drill rod with lapping compound or with a slurry of carborundum powder and oil.

NOTE 13 - While not required, some laboratories polish both sides of the rotor. To do this, the rotor is installed on a used pump shaft, and the small end of the shaft is placed in a drill press. Both sides of the rotor are polished with 400 wet paper and oil and then finish polished with 600 wet paper and oil.

Vigorous lapping might have a detrimental effect on the rotor strength. Depending on how the lapping is done, this could cause an imbalance in the compressive residual stresses on the surface of the metal. These stresses are induced by the carburizing and hardening process and are a major factor in developing the rotor fatigue strength.

NOTE 14 - While not required, some laboratories polish the bushings in an attempt to minimize internal pump leakage at elevated pressures and temperatures. This polishing is done on a piece of crocus cloth or 400 wet paper with plate glass or a surface plate under it. The polishing (circular motion) is continued until the outer 6 mm (1/4 in.) of the bushing is flat with all tool marks removed. The bushings are then finish polished in the same manner using 600 wet paper or polishing paper. Coating the outer 6 mm (1/4 in.) of the inner surface of the bushing with Prussian blue dye before polishing will aid in determining whether that portion of the bushing is flat.

6.2.4 Clean the cartridge parts in Stoddard Solvent, rinse with precipitation naphtha (Warning - see Note 15) and air dry.

NOTE 15 - Warning: Extremely flammable. Harmful if inhaled. Vapors can cause flash fire.

6.2.5 Measure the rotor width between each vane slot and the ring width at twelve places equally spaced around the ring. Measure the width of each vane at top and bottom. Record all measurements. Both the top and bottom vane widths must be 2.5 to 15.2 µm (0.001 to 0.0006 in.) less than the average rotor width, and the average rotor width must be 17.8 to 35.6 µm (0.0007 to 0.0014 in.) less than the average ring width.

6.2.6 Weigh (separately) the cam ring and the complete set of twelve vanes. Determine these two weights to the nearest milligram and record these values. The vanes should be checked to see if they have been magnetized. They must not be magnetized when weighing before or after test. Vanes may be demagnetized with a degausser.

6.2.7 Assemble the test cartridge, wetting all parts with a film of test fluid and making certain of proper vane insertion into the rotor and correct rotor and inner and outer bushing direction and alignment (see Fig. 2). The vanes should be checked for free movement in rotor slots when assembling.

NOTE 16 - Tight vanes will often fit freely in another slot.

6.2.8 Insert and bottom the assembly alignment pin, only about 3 mm (1/8 in.) of the large end should be visible above the outer bushing surface.

6.3 Installation of Test Cartridge:

6.3.1 Insert a properly prepared pump test cartridge into the pump housing, being careful to completely seat it using the guide pin hole for right hand rotation (small hole near inlet of pump housing).

6.3.2 Install pump housing head and gasket.

NOTE 17 - The following torque sequence has been found satisfactory. Use a torque wrench to tighten the eight head bolts, 1100 N-mm (10 in.-lb) at a time, using the following sequence: Top (1), Bottom (5), Right Side (3), Left Side (7), then bolts (2), (6), (4), and (8). Slowly rotate the pump shaft by hand while tightening the bolts. Tighten bolts until binding is felt. Then, loosen the head bolts until the shaft is completely free and re-torque 1100 N-mm (10 in.-lb) at a time, to 1100 N-mm (10 in.-lb) less than the above binding point. Record the final level of torque (usually about 11300 to 17000 N-mm (100 to 140 in.-lb). The pump should rotate with a slight drag on the shaft but there should be no binding.

NOTE 18 - While not required, some laboratories disconnect the pump to motor shaft coupling during torquing to eliminate the drag of the motor while rotating the pump shaft.

NOTE 19 - Bind is characterized by: (a) a catch or tight spot in an otherwise smooth shaft rotation; (b) a smooth revolving pump shaft with immediate stoppage after turning effort is stopped; or (c) complete seizure or stoppage requiring abnormal hand effort to turn the shaft, or all of these.

NOTE 20 - If binding occurs at less than 5600 N-mm (50 in.-lb) there probably is a misalignment within the pump and it should be disassembled.

6.4 Test Start-up and Operation:

6.4.1 Close all drain valves and petcocks and open the reservoir valve to allow the test fluid to fill the pump housing and test system's lower lines.

6.4.2 Reduce the setting of the pressure control valve and turn off cooling water if not already done.

6.4.3 Jog the pump drive motor ON and OFF switches until fluid is returned to the reservoir.

6.4.4 Start the pump and adjust the speed to 1200 r/min.

6.4.5 Observe the fluid in the reservoir to make sure that it is clear and does not contain noticeable amounts of entrained air before increasing pressure.

NOTE 21 - If fluid cannot be visually observed in the reservoir, the lack of pump noise can be an acceptable indication that the fluid is suitably deaerated.

6.4.6 Adjust pump outlet pressure to 2.07 MPa (300 psi).

6.4.7 Warm up for 1 h in six 10-min steps, at increased pressure levels. The pressure levels are 2.07, 4.14, 6.21, 6.89, 10.34, and 12.41 MPa (300, 600, 900, 1000, 1500, and 1800 psi). During this warm-up period, pump inlet temperature will be rising. When this temperature is within 3°C (5°F) of the control level, start to apply cooling through the heat exchanger system to minimize temperature override on the test fluid.

NOTE 22 - If pump vane noise (chatter) is heard during the warm up, the pump can be shut down and the pump head bolts tightened in 0.560 N•m (5-in. lb) increments, using the same tightening sequence as described in 4.3.2, in an effort to eliminate the noise.

6.4.8 Make certain that pump speed and pump inlet temperature are at test conditions, and adjust pump outlet pressure to 13.79 MPa (2000 psi).

NOTE 23 - Do not start test if pressure gage shows evidence of unusual relief valve fluctuation or pulsations.

6.4.9 Measure and record fluid flow rate.

6.4.10 Record clock time or adjust test system timer to zero and consider this the start of test.

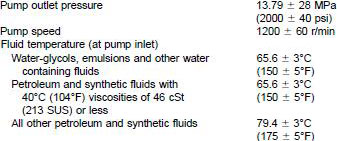

6.4.11 Operate system at the following conditions uninterrupted for 100 h or until operating difficulties dictate test termination.

6.4.12 It is not acceptable to replace any pump cartridge components during test. The test should be terminated in the event of low flow, low pressure, or excessive noise or leaking.

NOTE 24 - Precaution: The test pump is rated at 6.89 MPa (1000 psi) but is being operated at 13.79 MPa (2000 psi). A protective shield around the pump is therefore recommended.

6.5 Test Shut-Down and Final Parts Inspection:

6.5.1 After completion of the 100-h test, reduce the pressure control valve setting and stop pump operation.

6.5.2 Stop the flow of the cooling water.

6.5.3 Observe and record the condition of the test fluid noting any unusual appearance or odor.

6.5.4 Open all drain valves and drain the test system.

6.5.5 Remove the pump head and carefully remove the test cartridge.

NOTE 25 - The use of a bent piano wire inserted through an inlet or outlet port to catch and hold the inner bushing or the use of needle nose pliers to grasp the outer bushing and the rotor hub, or both, facilitates removal of the cartridge.

6.5.6 Observe and record the condition of the reservoir surfaces noting any deposits. System preparation for additional testing as in 6.1 can now proceed.

6.5.7 Carefully disassemble the test cartridge and inspect the individual pump cartridge parts for signs of wear, deposit formation or discoloration. Record any observations.

6.5.8 Remove all deposits from the test cartridge cam ring and vanes by thorough cleaning. Rinse in precipitation naphtha and air dry.

6.5.9 Weigh (separately) the used cam ring and the set of twelve used vanes to the nearest milligram. Record these two weights and their total.

6.5.10 Subtract the after test total weight (cam ring plus twelve vanes) from the unused weight total to determine the weight loss sustained during the run.