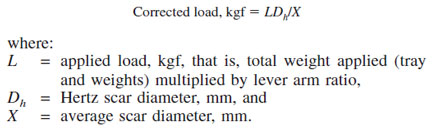

10.1 Corrected Load - Calculate and record (Table 1, Column 5) for each applied load between the last nonseizure load and weld point using the equation

10.2 Load-Wear Index - Calculate and report the load-wear index (formerly Mean-Hertz Load) in kilograms-force using the equation:

Load - wear index, kgf = A/10

where:

A = sum of the corrected loads determined for the ten applied loads immediately preceding the weld point (see Note 13).

NOTE 13 - If tests applied to the lubricant indicate it follows the compensation line, then A may be defined as:

A = sum of corrected loads plus compensation line corrected loads, or the ten applied loads preceding the weld point. For convenience, Table 2 has been constructed to give the compensation line corrected load for any portion of the compensation line. This value is obtained by noting the intersection of the last nonseizure load and weld load values. For example: the last nonseizure load of a lubricant was found to be 490N (50kgf). Subsequent runs in the seizure portion of the curve were made at 618, 784, 981, 1236, and 1569-N (63, 80, 100, 126 and 160-kgf) loads with weld-point found to be 1961 N (200 kgf). Table 2 notes the value at intersection of 490 and 1961 N (50 and 200 kgf) to be 145 6N (148.6 kgf). This value, the compensation line corrected load, was obtained by correcting loads of 490, 392, 314, 235 and 196N (50, 40, 32, 24 and 20 kgf) using compensation line scar diameters.This fulfills the definition of load-wear index, that a total of eleven runs be made, the eleventh run causing welding of the test balls. If the tests applied to the lubricant indicate the wear scars do not follow the compensation line, then Table 2 can not be applied and actual determinations must be made for all ten applied loads preceding the weld point.

10.3 Weld Point - Report the verified weld point as found in 9.10.