3.1 Definitions:

3.1.1 compensation line - a line of plot on logarithmic paper, as shown in Fig.1, where the coordinates are scar diameter in millimetres and applied load in kilograms-force (or newtons), obtained under dynamic conditions.

3.1.1.1 Discussion - Coordinates for the compensation line are found in Table 1, Columns 1 and 3.

3.1.1.2 Discussion - Some lubricants give coordinates which are above the compensation line. Known examples of such fluids are methyl phenyl silicone, chlorinated methyl phenyl silicone, silphenylene, phenylether, and some mixtures of petroleum oil and chlorinated paraffins.

3.1.2 compensation scar diameter - the average diameter, in millimetres, of the wear scar on the stationary balls caused by the rotating ball under an applied load in the presence of a lubricant, but without causing either seizure or welding.

3.1.2.1 Discussion - The wear scar obtained shall be within 5% of the values noted in Table 1, Column 3.

3.1.3 corrected load - the load in kilograms-force (or newtons) for each run obtained by multiplying the applied load by the ratio of the Hertz scar diameter to the measured scar diameter at that load.

3.1.4 Hertz line - a line of plot on logarithmic paper, as shown in Fig. 1, where the coordinates are scar diameter in millimetres and applied load in kilograms-force (or newtons), obtained under static conditions.

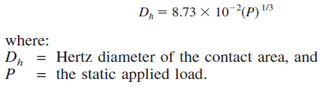

3.1.5 Hertz scar diameter - the average diameter, in millimetres, of an indentation caused by the deformation of the balls under static load (prior to test). It may be calculated from the equation

3.1.6 immediate seizure region - that region of the scar-load curve characterized by seizure or welding at the startup o by large wear scars. Initial defiection of indicating pen on the optional friction-measuring device is larger than with nonseizure loads. See Fig.1.

3.1.7 incipient seizure or initial seizure region - that region at which, with an applied load, there is a momentary breakdown of the lubricating film. This breakdown is noted by a sudden increase in the measured scar diameter and a momentary deflection of the indicating pen of the optional friction-measuring device. See Fig.1.

3.1.8 last nonseizure load—the last load at which the measured scar diameter is not more than 5% above the compensation line at the load. See Fig.1.

3.1.9 load-wear index (or the load-carrying property of a lubricant) - an index of the ability of a lubricant to minimize wear at applied loads. Under the conditions of this test, specific loadings in kilograms-force (or newtons) having intervals of approximately 0.1 logarithmic units, are applied to the three stationary balls for ten runs prior to welding. The load-wear index is the average of the sum of the corrected loads determined for the ten applied loads immediately preceding the weld pair.

3.1.10 weld point - under the conditions of this test, the lowest applied load in kilograms at which the rotating ball welds to the three stationary balls, indicating the extreme-pressure level of the lubricants-force (or newtons) has been exceeded.

3.1.10.1 Discussion - Some lubricants do not allow true welding, and extreme scoring of the three stationary balls results. In such cases, the applied load which produces a maximum scar diameter of 4mm is reported as the weld point.