7. Apparatus

7.1 Engine Equipment - This test method uses a single cylinder, CFR engine that consists of standard components as follows: crankcase, a cylinder/clamping sleeve assembly to provide continuously variable compression ratio adjustable with the engine operating, a thermal syphon recirculating jacket coolant system, a multiple fuel tank system with selector valving to deliver fuel through a single jet passage and carburetor venturi, an intake air system with controlled temperature and humidity equipment, electrical controls, and a suitable exhaust pipe. The engine flywheel is belt connected to a special electric power-absorption motor utilized to both start the engine and as a means to absorb power at constant speed when combustion is occurring (engine firing). See Fig. 1.

7.1.1 See Annex A2 for details and description of all critical, non-critical, and equivalent engine equipment.

7.2 Instrumentation - This test method uses electronic detonation metering instrumentation to measure the intensity of combustion knock as well as conventional thermometry, gages, and general purpose meters.

7.2.1 See Annex A3 for details and description of all critical, non-critical, and equivalent instrumentation.

7.3 Reference and Standardization Fuel Dispensing Equipment - This test method requires repeated blending of reference fuels and TSF materials in volumetric proportions. In addition, blending of dilute tetraethyllead in isooctane may be performed on-site for making rating determinations above 100 O.N. Blending shall be performed accurately because rating error is proportional to blending error.

7.3.1 Volumetric Blending of Reference Fuels - Volumetric blending has historically been employed to prepare the required blends of reference fuels and TSF materials. For volumetric blending, a set of burets, or accurate volumetric apparatus, shall be used and the desired batch quantity shall be collected in an appropriate container and thoroughly mixed before being introduced to the engine fuel system.

7.3.1.1 Calibrated burets or volumetric apparatus having a capacity of 200 to 500 mL and a maximum volumetric tolerance of more or less 0.2 % shall be used for preparation of reference and standardization fuel blends. Calibration shall be verified in accordance with Practice E 542.

7.3.1.2 Calibrated burets shall be outfitted with a dispensing valve and delivery tip to accurately control dispensed volume. The delivery tip shall be of such design that shut-off tip discharge does not exceed 0.5 mL.

7.3.1.3 The rate of delivery from the dispensing system shall not exceed 400 mL per 60 s.

7.3.1.4 The set of burets for the reference and standardization fuels shall be installed in such a manner and be supplied with fluids such that all components of each batch or blend are dispensed at the same temperature.

7.3.1.5 See Appendix X1 for volumetric reference fuel dispensing system information.

7.3.2 Volumetric Blending of Tetraethyllead - A calibrated buret, pipette assembly, or other liquid dispensing apparatus having a capacity of not more than 4.0 mL and a critically controlled volumetric tolerance shall be used for dispensing dilute tetraethyllead into 400-mL batches of isooctane. Calibration of the dispensing apparatus shall be verified in accordance with Practice E 542.

7.3.3 Gravimetric Blending of Reference Fuels - Use of blending systems that allow preparation of the volumetrically-defined blends by gravimetric (mass) measurements based on the density of the individual components is also permitted, provided the system meets the requirement for maximum 0.2 % blending tolerance limits.

7.3.3.1 Calculate the mass equivalents of the volumetrically-defined blend components from the densities of the individual components at 15.56°C (60°F).

7.4 Auxiliary Apparatus:

7.4.1 Special Maintenance Tools - A number of specialty tools and measuring instruments should be utilized for easy, convenient, and effective maintenance of the engine and testing equipment. Lists and descriptions of these tools and instruments are available from the manufacturer of the engine equipment and those organizations offering engineering and service support for this test method.

7.4.2 Ventilation Hoods - Handling of reference and standardization fuels, dilute tetraethyllead, and test samples having various hydrocarbon compositions is best conducted in a well ventilated space or in a laboratory hood where air movement across the area is sufficient to prevent operator inhalation of vapors.

7.4.2.1 General purpose laboratory hoods are typically effective for handling hydrocarbon fuel blending.

7.4.2.2 A blending hood meeting the requirements for dispensing toxic material shall be utilized in testing laboratories that choose to prepare leaded isooctane PRF blends on-site.

8. Reagents and Reference Materials

8.1 Cylinder Jacket Coolant - Water shall be used in the cylinder jacket for laboratory locations where the resultant boiling temperature shall be 100 more or less 1.5°C (212 more or less 3°F). Water with commercial glycol-based antifreeze added in sufficient quantity to meet the boiling temperature requirement shall be used when laboratory altitude dictates. A commercial multi-functional water treatment material should be used in the coolant to minimize corrosion and mineral scale that can alter heat transfer and rating results. (Warning - Ethylene glycol based antifreeze is poisonous and may be harmful or fatal if inhaled or swallowed. See Annex A1.)

8.1.1 Water shall be understood to mean reagent water conforming to Type IV, of Specification D1193.

8.2 Engine Crankcase Lubricating Oil - An SAE 30 viscosity grade oil meeting the current API service classification for spark-ignition engines shall be used. It shall contain a detergent additive and have a kinematic viscosity of 9.3 to 12.5 mm2 per s (cSt) at 100°C (212°F) and a viscosity index of not less than 85. Oils containing viscosity index improvers shall not be used. Multigraded oils shall not be used. (Warning - Lubricating oil is combustible and its vapor is harmful. See Annex A1.)

8.3 PRF, isooctane and normal heptane classified as reference fuel grade and meeting the specifications that follow: (Warning - Primary reference fuel is flammable and its vapors are harmful. Vapors may cause flash fire. See Annex A1.)

8.3.1 Isooctane (2,2,4-trimethylpentane) shall be no less than 99.75 % by volume pure, contain no more than 0.10 % by volume n-heptane, and contain no more than 0.5 mg/L (0.002 g/U.S. gal) of lead.11 (Warning - Isooctane is flammable and its vapors are harmful. Vapors may cause flash fire. See Annex A1.)

8.3.2 n-heptane shall be no less than 99.75 % by volume pure, contain no more than 0.10 % by volume isooctane and contain no more than 0.5 mg/L (0.002 g/U.S. gal) of lead. (Warning - n-heptane is flammable and its vapors are harmful. Vapors may cause flash fire. See Annex A1.)

8.3.3 80 octane PRF blend, prepared using reference fuel grade isooctane and n-heptane shall contain 80 more or less 0.1 % by volume isooctane. (Warning - 80 octane PRF is flammable and its vapors are harmful. Vapors may cause flash fire. See Annex A1.)

8.3.4 Refer to Annex A5 for octane numbers of various blends of 80 octane PRF and either n-heptane or isooctane (Table A5.2).

8.4 Dilute Tetraethyllead (Commonly referred to as TEL Dilute Volume Basis) is a prepared solution of aviation mix tetraethyllead antiknock compound in a hydrocarbon diluent of 70 % (V/V) xylene, 30 % (V/V) n-heptane. (Warning - Dilute tetraethyllead is poisonous and flammable. It may be harmful or fatal if inhaled, swallowed, or absorbed through the skin. May cause flash fire. See Annex A1.)

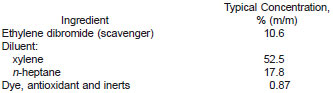

8.4.1 The fluid shall contain 18.23 more or less 0.05 % (m/m) tetraethyllead and have a relative density 15.6/15.6°C (60/60°F) of 0.957 to 0.967. The typical composition of the fluid, excluding the tetraethyllead, is as follows:

8.4.2 Add dilute tetraethyllead, in millilitre quantities, to a 400-mL volume of isooctane to prepare PRF blends used for ratings over 100 O.N. The composition of the dilute fluid is such that when 2.0 mL are added to 400 mL of isooctane, the blend shall contain the equivalent of 2.0 mL of lead/U.S. gal (0.56 g of lead/L).

8.4.3 Refer to Annex A5 for octane numbers of blends of tetraethyllead and isooctane (see Table A5.3).

8.5 Toluene, Reference Fuel Grade shall be no less than 99.5 % by volume pure. Peroxide number shall not exceed 5 mg per kg (ppm). Water content shall not exceed 200 mg per kg. (Warning - Toluene is flammable and its vapors are harmful. Vapors may cause flash fire. See Annex A1.)

8.5.1 Antioxidant shall be added by the supplier at a treat rate suitable for good long term stability as empirically determined with the assistance of the antioxidant supplier.

8.6 Check Fuels are in-house typical spark-ignition engine fuels having selected octane numbers, low volatility, and good long term stability. (Warning - Check Fuel is flammable and its vapors are harmful. Vapors may cause flash fire. See Annex A1.)

9. Sampling

9.1 Collect samples in accordance with Practices D4057, D4177, or D5842.

9.2 Sample Temperature - Samples shall be cooled to a temperature of 2 to 10°C (35 to 50°F), in the container in which they are received, before the container is opened.

9.3 Protection from Light - Collect and store sample fuels in an opaque container, such as a dark brown glass bottle, metal can, or a minimally reactive plastic container to minimize exposure to UV emissions from sources such as sunlight or fluorescent lamps.