4. Summary of Test Method

4.1 The Research O.N. of a spark-ignition engine fuel is determined using a standard test engine and operating conditions to compare its knock characteristic with those of PRF blends of known O.N. Compression ratio and fuel-air ratio are adjusted to produce standard K.I. for the sample fuel, as measured by a specific electronic detonation meter instrument system. A standard K.I. guide table relates engine C.R. to O.N. level for this specific method. The fuel-air ratio for the sample fuel and each of the primary reference fuel blends is adjusted to maximize K.I. for each fuel.

4.1.1 The fuel-air ratio for maximum K.I. may be obtained (1) by making incremental step changes in mixture strength, observing the equilibrium K.I. value for each step, and then selecting the condition that maximizes the reading or (2) by picking the maximum K.I. as the mixture strength is changed from either rich-to-lean or lean-to-rich at a constant rate.

4.2 Bracketing Procedures - The engine is calibrated to operate at standard K.I. in accordance with the guide table. The fuel-air ratio of the sample fuel is adjusted to maximize the K.I., and then the cylinder height is adjusted so that standard K.I. is achieved. Without changing cylinder height, two PRF blends are selected such that, at their fuel-air ratio for maximum K.I., one knocks harder (higher K.I.) and the other softer (lower K.I.) than the sample fuel. A second set of K.I. measurements for sample fuel and PRF blends is required, and the sample fuel octane number is calculated by interpolation in proportion to the differences in average K.I. readings. A final condition requires that the cylinder height used shall be within prescribed limits around the guide table value for the calculated O.N. Bracketing procedure ratings may be determined using either the equilibrium fuel level or dynamic fuel level fuel-air ratio approach.

4.3 C.R. Procedure - A calibration is performed to establish standard K.I. using the cylinder height specified by the guide table for the O.N. of the selected PRF. The fuel-air ratio of the sample fuel is adjusted to maximize the K.I. under equilibrium conditions; the cylinder height is adjusted so that standard K.I. is achieved. The calibration is reconfirmed and the sample fuel rating is repeated to establish the proper conditions a second time. The average cylinder height reading for the sample fuel, compensated for barometric pressure, is converted directly to O.N., using the guide table. A final condition for the rating requires that the sample fuel O.N. be within prescribed limits around that of the O.N. of the single PRF blend used to calibrate the engine to the guide table standard K.I. condition.

5. Significance and Use

5.1 Research O.N. correlates with commercial automotive spark-ignition engine antiknock performance under mild conditions of operation.

5.2 Research O.N. is used by engine manufacturers, petroleum refiners and marketers, and in commerce as a primary specification measurement related to the matching of fuels and engines.

5.2.1 Empirical correlations that permit calculation of automotive antiknock performance are based on the general equation:

Road O.N. = (k1 x Research O.N.) + (k2 x Motor O.N.) + k3

Values of k1, k2, and k3 vary with vehicles and vehicle populations and are based on road-O.N. determinations.

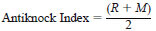

5.2.2 Research O.N., in conjunction with Motor O.N., defines the antiknock index of automotive spark-ignition engine fuels, in accordance with Specification D4814. The antiknock index of a fuel approximates the Road octane ratings for many vehicles, is posted on retail dispensing pumps in the U.S., and is referred to in vehicle manuals.

Antiknock index = 0.5 Research O.N. + 0.5 Motor O.N. + 0

This is more commonly presented as:

5.2.3 Research O.N. is also used either alone or in conjunction with other factors to define the Road O.N. capabilities of spark-ignition engine fuels for vehicles operating in areas of the world other than the United States.

5.3 Research O.N. is used for measuring the antiknock performance of spark-ignition engine fuels that contain oxygenates.

5.4 Research O.N. is important in relation to the specifications for spark-ignition engine fuels used in stationary and other nonautomotive engine applications.

6. Interferences

6.1 Precaution - Avoid exposure of sample fuels to sunlight or fluorescent lamp UV emissions to minimize induced chemical reactions that can affect octane number ratings.

6.1.1 Exposure of these fuels to UV wavelengths shorter than 550 nm for a short period of time may significantly affect octane number ratings.

6.2 Certain gases and fumes that can be present in the area where the knock testing unit is located may have a measurable effect on the Research O.N. test result.

6.2.1 Halogenated refrigerant used in air conditioning and refrigeration equipment can promote knock. Halogenated solvents can have the same effect. If vapors from these materials enter the combustion chamber of the CFR engine, the Research O.N. obtained for sample fuels can be depreciated.

6.3 Electrical power subject to transient voltage or frequency surges or distortion can alter CFR engine operating conditions or knock measuring instrumentation performance and thus affect the Research O.N. obtained for sample fuels.