9. Report

9.1 Report the apparent viscosity at a given temperature with the spindle number and speed used to obtain the data as:

Apparent viscosity, 325 mPa·s at 120°C

(No. 2 spindle, 30 rpm)

10. Precision and Bias

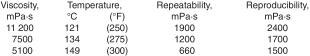

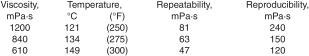

10.1 The composition of a hot melt influences the precision to be expected when testing different types of samples. The following data should be used to judge the acceptability of results (95 % probability) for four different types of hot melts according to the concept of precision as given in Practice E180.

10.2 Duplicate results should be considered suspect if they differ by more than the following amounts for each of the four types listed: below:

10.2.1 High-Viscosity Sample, M1-65-20:

58 weight % of a 68°C (155°F) melting point wax.

42 weight % of an ethylene-vinyl acetate copolymer containing 27 to 29 % vinyl acetate and having a melt index of from 12 to 18.

10.2.2 Medium-Viscosity Sample, MI-65-21:

72 weight % of a 61°C (142°F) melting point wax.

28 weight % of the same copolymer used in sample MI-65-20.

10.2.3 Low-Viscosity Sample, MI-65-22:

96.3 weight % of a 77°C (170°F) melting point microcrystalline wax.

2.7 weight % of butyl rubber.

10.2.4 Low-Viscosity Sample, MI-65-23:

80 weight % of a 68°C (154°F) melting point wax.

20 weight % of a 5000 molecular weight polyethylene having a melting point from 107 to 111°C (224 to 232°F), a specific gravity of 0.92 and a typical viscosity at 140°C of 4 Pa·s.

10.3 Bias - The procedure in this test method has no bias because the value of apparent viscosity can be defined only in terms of a test method.

11. Keywords

11.1 apparent viscosity; hot melts; petroleum waxes; waxes