ASTM D2622 standard test method for sulfur in petroleum products by wavelength dispersive X-ray fluorescence spectrometry

14. Precision and Bias

14.1 The precision of the test method was determined by statistical analysis of results obtained an interlaboratory study that included 27 samples including gasolines, distillates, biodiesel, residual oils, and crude oils. A pooled limit of quantitation (PLOQ) of approximately 3 mg/kg S was determined for all sample types. Precision for gasoline and diesel samples, as well as for high-power and low-power source XRF instruments is included in Appendix X1. The ranges of sulfur concentrations represented by the sample sets, together with the precisions, are listed in 14.1.1 and 14.1.2. These statistics apply only to samples having less than the level of interfering materials present shown in Table 1 (see also 1.4).

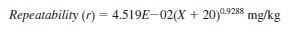

14.1.1 Repeatability - The difference between successive test results obtained by the same operator with the same apparatus under constant operating conditions on identical test material would, in the long run, in the normal and correct operation of the test method exceed the following values only in one case in twenty. Repeatability (r) may be calculated as shown in Eq 12 for all materials covering the full scope of this method. See Table 4 for calculated values.

where:

X = sulfur concentration in mg/kg total sulfur.

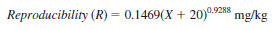

14.1.2 Reproducibility - The difference between two single and independent results obtained by different operators working in different laboratories on identical test material would, in the long run, in the normal and correct operation of the test method exceed the following values only in one case in twenty. Reproducibility (R) may be calculated as shown in Eq 13 for all materials covering the full scope of this method. See Table 4 for calculated values.

where:

X = sulfur concentration in mg/kg total sulfur.

14.1.3 Repeatability and reproducibility values for gasoline and diesel in the aforementioned interlaboratory study6 may be found in Appendix X1. Also, precision values and plots for high power (>1KW source) instruments are also included.

14.2 Bias - The interlaboratory study included ten NIST standard reference materials (SRM's). The certified sulfur value, interlaboratory round robin (RR) value, measured C/H, apparent bias, and relative bias are given in Table 5. Table 6 compares NIST value with sulfur concentrations corrected for C/H ratio. The white oil was assumed to have a C/H mass ratio of 5.698 (C22H46).

14.2.1 The variation in relative sulfur sensitivity as a function of C/H mass ratio is shown graphically in Fig. 1.

14.2.2 Based on the analysis of 10 NIST Standard Reference Materials (SRM's), there was no significant bias between the certified values and the results obtained in this interlaboratory study for any SRM or sample type within measured reproducibilities (R), especially after the C/H ratio corrections were applied (see Tables 5 and 6).

15. Keywords

15.1 analysis; diesel; gasoline; jet fuel; kerosene; petroleum; spectrometry; sulfur; wavelength dispersive x-ray fuorescence; X-ray