5. Apparatus

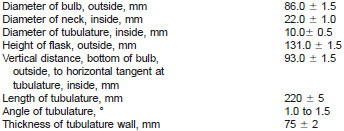

5.1 Flask - A side-arm distillation flask, as shown in Fig. 1, having the following dimensions:

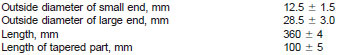

5.2 Condenser Tube - A tapered glass condenser, as shown in Fig. 2, having the following dimensions:

5.3 Source of Heat - Electric heater, 750-W, with variable transformer control as shown in Fig. 2, with a direct-reading voltmeter (120 V) or ammeter (5 A). Transformer settings shall be reproducible within 2 % on the percent input dial. The heater shall be fitted with an upper refractory top, with the dimensions shown in Fig. 3, and a 110-mm square plate of 6-mm thick non-asbestos containing cement board, having an 80-mm center hole as shown in Fig. 4.

5.4 Shield - A stainless steel shield with mica windows lined with 3-mm thick high temperature cloth, provided with a two-piece cover of 6-mm thick transite board (non-asbestos) of the form and dimensions shown in Fig. 4.

5.5 Receivers - Erlenmeyer flasks or beakers, having a nominal capacity of 50 to 125 mL and tared to the nearest 0.05 g.

5.6 Thermometer - An ASTM High Distillation Thermometer, having a range from -2 to 400°C and conforming to the requirements for Thermometer 8C as prescribed in Specification E 1 or a suitable digital thermometer with the same precision as 8C.

5.7 Timer - Stop clock or stop watch, calibrated in seconds or tenths.

6. Sampling

6.1 Samples from bulk shipments shall be taken in accordance with Practice D140, and shall be free of foreign substances. Thoroughly mix the sample before withdrawing a representative portion for the determination or for dehydration.

6.2 Hard Pitch - If the solid sample contains free water, air-dry a representative portion.

6.3 Soft Pitch - If the presence of water is indicated by surface foam on heating, maintain a representative portion at a temperature between 125 and 150°C in an open container until foaming ceases. Do not overheat, and immediately remove from the heat source when the foam subsides.