10. Calculation and Report

10.1 Report the OK and score values in terms of the masses (weights) placed on the mass (weight) pan hanging from the end of the load-lever arm; do not include the mass (weight) of the pan assembly. Report the values in multiples of 2.27 kg (5 lb) above 13.71 kg (30 lb) and in multiples of 1.36 kg (3 lb) below 30 lb.

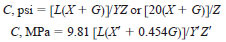

10.2 When desired, the contact (unit) pressure which exists between the cup and block at the conclusion of the test may be calculated. After the OK value has been determined, remove the test block and wash with Stoddard solvent, rinse with acetone, and blow dry. By means of a filar micrometer microscope, measure the width of the scars on those blocks which successfully carried this load. Make all measurements to 0.05 mm (0.002 in.) Calculate the contact pressure, C, as follows:

where:

L = 10 = mechanical advantage of load-lever arm,

G = load-lever constant (value is stamped on lever arm of each tester),

X = mass (weight) placed on the weight pan, lb

X' = mass (weight) placed on the weight pan, kg,

Y = length of test scar (1/2 in.),

Y' = length of test scar (12.7 mm),

Z = average width of test scar, in., and

Z' = average width of test scar, mm.

11. Precision and Bias

11.1 The precision of this test is not known to have been obtained in accordance with currently accepted guidelines (for example, Research Report RR:D02-1007).

11.2 The following criteria should be used for judging the acceptability of OK load results (95 % confidence):

11.2.1 Repeatability - Duplicate results by the same operator should be considered suspect if they differ by more than 23 % of their mean. Table X3.1, based on this level of repeatability, and the use of the load increments specified in the method, may be used to quickly check the acceptability of the results by the same operator.

11.2.2 Reproducibility - The results submitted by each of two laboratories should be considered suspect if they differ by more than 59 % of their mean. Table X3.2, based on this level of reproducibility and the use of the load increments specified in the method, may be used to quickly check the acceptability of two results, each from a different laboratory.

11.3 Bias - The procedure in Test Method D2509 for measuring load-carrying properties of lubricating grease has no bias because the value of load-carrying properties can be defined only in terms of a test method.

NOTE 4 - These precision data were derived from tests by 14 laboratories on five greases whose average Timken OK loads ranged from approximately 18.14 kg to 24.98 kg (40 lb to 65 lb). These results have been published in the NLGI Spokesman, Vol. XL No. 10, January 1978, pp. 342–351.

12. Keywords

12.1 EP; extreme pressure; grease; grease load-carrying capacity; Timken