5. Apparatus

5.1 Aging (Oxidation) Bath - An oil bath, wax bath, or aluminum block heater (see IEC Standard 61125) of a suitable type capable of controlling the temperature at 110 more or less 0.5°C with a temperature gradient of less than 1°C in the body of the liquid. Use any nontoxic liquid having low volatility at 110°C and containing no volatile additives and having a flash point above the test temperature. Mineral oils, waxes and silicone oils have been used satisfactorily. Circulation of the oil or wax heating medium by means of a pump or stirrer is recommended. See also 5.4, relating to the depth of fluid in aging bath and position of oil receptacles.

5.2 Drying Tower - A drying tower 25 to 30 cm in height, fitted with a ground-glass stopper and side tubes for conditioning of the oxygen supply.

5.3 Oil Receptacle and Head - An oil receptacle consisting of a heat-resistant glass test tube 25 mm in outside diameter, 1.25 mm in wall thickness, 210 mm in overall length including a standard taper 24/40 outer joint, with a Dreschsel-type head consisting of a standard taper 24/40 inner joint with side outlet tube 5.0 mm in outside diameter and an oxygen delivery tube 5.0 mm in outside diameter and 3 mm, minimum, in inside diameter which extends to within 2.5 more or less 0.5 mm of the bottom of the oil receptacle and has its end ground at an angle of 30°to the axis of the tube. The design is shown in Fig. 1.

5.4 Position the oil receptacle in the aging bath in accordance with the drawing shown in Fig. 2.

NOTE 3 - The oil receptacle and position in the aging bath are essentially the same as specified in IEC Standard 61125, "Test Method for Oxidation Stability of Inhibited Mineral Insulating Oils", Glassware dimensions have been altered slightly to conform to sizes readily available in the United States.

5.5 Filtering Crucibles - A glass filter crucible having a maximum diameter of the pores between 5 and 15 µm as determined in accordance with the method described in the Appendix. Cellulose ester type membrane filters of 5-µm porosity have been used successfully also.

6. Reagents and Materials

6.1 Purity of Reagents - Use reagent grade chemicals in all tests. Unless otherwise indicated, all reagents are to conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where such specifications are available.

6.2 Chloroform, cp, or acetone, cp.

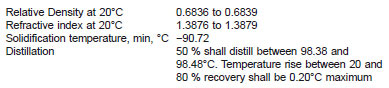

6.3 n-Heptane, for dilution of the oxidized oil, precipitation, and washing of the sludge shall conform to the following requirements:

6.4 p-Naphtholbenzein Indicator Solution - The specifications for p-naphtholbenzein are prescribed in Test Method D974. Prepare a solution containing 10 g p-naphtholbenzein per litre of titration solvent (see 6.7).

6.5 Oxygen - Obtained from liquid oxygen, minimum purity 99.4 %.

6.6 Potassium Hydroxide Solution, Standard Alcoholic (0.1 N) - Prepare alcoholic potassium hydroxide solution and standardize as described in Test Method D 974. Commercially prepared Alcoholic Potassium Hydroxide Solution is available.

6.7 Titration Solvent - Mix 3 parts by volume of toluene with 2 parts by volume of isopropyl alcohol.

6.8 Silicon Carbide Abrasive Cloth, 100-grit with cloth backing.

6.9 Wire Catalyst - AWG No. 18 (0.0403-in. (1.01-mm) diameter) 99.9 % purity conforming to Specification B 1. Soft-drawn copper wire of equivalent grade may also be used.

6.10 Hydrochloric Acid, 10 Volume %.

7. Hazards

7.1 Consult Material Safety Data Sheets for all materials used in this test method.