5. Apparatus

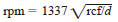

5.1 Centrifuge, meeting all the safety requirements for normal use and capable of whirling two or more filled centrifuge tubes at a speed which can be controlled to give a relative centrifugal force (rcf) between 600 and 700 at the tip of the tubes. The revolving head, trunnion rings, and trunnion cups, including the rubber cushion, shall be soundly constructed to withstand the maximum centrifugal force capable of being delivered by the power source. The trunnion cups and cushions shall firmly support the tubes when the centrifuge is in motion. The centrifuge shall be enclosed by a metal shield or case strong enough to eliminate danger if any breakage occurs. Calculate the speed of the rotating head as follows:

where:

rcf = relative centrifugal force, and

d = diameter of swing, in millimetres, measured between tips of opposite tubes when in rotating position.

The relationship between the diameter swing, relative centrifugal force, and revolutions per minute is given in Table 1.

5.2 Centrifuge Tube, cone-shaped, conforming to the dimensions given in Fig. 1, and made of thoroughly annealed glass. The graduations, numbered as shown in Fig. 1, shall be clear and distinct, and the mouth shall be constructed in a shape suitable for closure with a cork. Scale-error tolerances and smallest graduations between various calibration marks are given in Table 2 and apply to calibrations made with redistilled mercury up to the 0.30-mL mark and distilled water for all remaining marks at 20°C.

6. Reagent

6.1 ASTM Precipitation Naphtha - Shall conform to the requirements given in Table 3. (Warning - Extremely flammable. See also Note 1.)

NOTE 1 - Precipitation naphtha is sometimes referred to or sold by other names such as petroleum naphtha, petroleum ether, ligroine, petroleum benzin, and industrial naphthas.

NOTE 2 - Before use, the naphtha should be free of any extraneous material which might affect the final test readings. For this purpose, it should either be filtered through a membrane filter or centrifuged several times and decanted just prior to its use.

7. Sampling

7.1 Refer to Practice D4057 (manual) or D4177 (automatic) for recommended practices for obtaining samples.

7.2 The sample shall be thoroughly representative of the material in question and the portion used for the test shall be thoroughly representative of the sample itself. This requires vigorous agitation of the sample immediately before transferring the sample to the tube. The difficulties in obtaining representative samples for this determination are unusually great; hence, the importance of sampling cannot be too strongly emphasized.