ASTM D2265 standard test method for dropping point of lubricating grease over wide temperature range

10. Calculation

10.1 Calculate the dropping point as follows:

DP = ODP + [(BT - ODP)/3]

where:

DP= dropping point,

ODP = thermometer reading when first drop reaches the bottom of the test tube, and

BT= block temperature when the drop falls.

11. Report

11.1 Report the following information:

11.1.1 Sample identification,

11.1.2 The corrected dropping point, and

11.1.3 The aluminum block oven temperature immediately after the drop was observed.

11.1.4 Follow local laboratory protocol for additional reportable requirements.

12. Precision and Bias

12.1 The precision of this test method is not known to have been obtained in accordance with currently accepted guidelines in Committee D-2 research report RR: D02-1007.

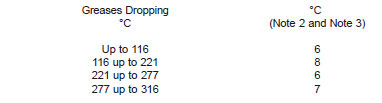

12.1.1 Repeatability - The difference between two test results obtained by the same operator with the same apparatus under constant operating conditions on identical test material would, in the long run, in the normal and correct operation of the test method, exceed the following values in only one case in twenty:

12.1.2 Reproducibility - The difference between two single and independent results obtained by different operators working in different laboratories on identical test material would, in the long run, in the normal and correct operation of the test method, exceed the following values in only one case in twenty:

12.2 Bias - There is no bias for this test method because the value of the dropping point can be defined only in terms of the test method.

NOTE 2 - When results do not agree within the limits shown, proceed as described in Practice D3244.

NOTE 3 - Values for greases dropping below 221°C based on the use of the older heavy wall temperature resistant tubes. Values for greases dropping above 221°C are based on the use of the thin wall test tube (6.1.2).

NOTE 4 - The dropping points of some greases, particularly those containing simple soaps, are known to decrease upon aging, the change being much greater than the deviation permitted in results obtained by different laboratories. Therefore, comparative tests between laboratories should be made within a period of six days.

NOTE 5 - The cooperative data given in NLGI Spokesman, Vol 31, 1967, p. 76, indicate that precision varied with dropping point range.

13. Keywords

13.1 dropping point; greases; lubricating grease

APPENDIX

(Nonmandatory Information)

X1. PRECISION VALUES

X1.1 The precision values shown in 12.1.1 and 12.1.2 were developed from the round robin of 1991 using seven greases: a lithium complex synthetic base, two lithium complex oil bases, two lithium 12-hydroxy stearates, an aluminum complex, and a polyurea.

X1.2 The original values for the deleted 343°C block temperature are noted below for informational purposes.

Repeatability 6°C

Reproducibility 24°C