6. Apparatus

6.1 Master Viscometers: Cannon or Ubbelohde Type - Acceptable viscometers are shown in Fig. 1 and Fig. 2. Two masters are required with calibration constants in the 0.001 to 0.003-mm2/s2 (cSt/s) range. Additional masters have factors increasing in three-fold steps.

6.2 Thermometers - Kinematic viscosity thermometers having a range from 18.5 to 21.5°C, or 38.5 to 41.5°C, and conforming to the requirements for Thermometers 44C and 120C, as prescribed in Specification E 1, and calibrated to 0.005°C by the National Institute of Standards and Technology or other qualified agency. A standard platinum resistance thermometer together with a Mueller resistance bridge having equivalent or better accuracy is preferable, where available. Other Thermometers 46C, 121C, etc. as required for standardizing oil viscosities at other temperatures may be used.

6.3 Bath - A thermostated bath containing water or other transparent liquid deep enough to immerse the master viscometers so that the upper fiducial mark is at least 50 mm below the surface. The efficiency of stirring and the balance between heat loss and input must be such that the temperature of the water does not vary by more than +/-0.01°C over the length of the viscometer or from one viscometer position to another. The working section of the bath should be shielded from direct radiation from heaters and lights. A standard platinum resistance thermometer, approximately 450 mm in length, may be used to ensure that the variation in temperature does not exceed +/-0.01°C. Firm supports should be provided to hold the master viscometer in a rigid and reproducible position within 0° 15 min of vertical.

6.4 Timer - Either a spring-wound or electric timer capable of measuring time intervals of 300 to 10 000 s with an accuracy of +/-0.03 %. The stop watch, fully but not tightly wound, must be used and tested in the same position. For example, if used at 45° inclination, it should have been tested previously in that position. Electric timers must be operated on circuits, the frequencies of which are controlled. Commercial power sources, the frequencies of which are intermittently and not continuously controlled, are not satisfactory. Both mechanical and electric timers can be sensitive to abnormally low ambient temperature and should not be used when cold.

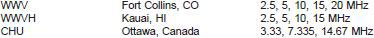

NOTE 1 - Time signals as broadcast by the National Institute of Standards and Technology are a convenient and primary standard reference for calibrating timing devices. The following can be used:

7. Reagents

7.1 Acetone, reagent grade.

NOTE 2 - Warning: Extremely flammable.

7.2 Chromic Acid Cleaning Solution - Carefully pour 1 L of concentrated sulfuric acid (H2SO4, relative density 1.84) into 35 mL of a saturated solution of technical grade sodium dichromate (Na2Cr2O7) in water. Strongly oxidizing acid cleaning solutions containing no chromium8 may be substituted to avoid disposal problems of chromium-containing solutions.

NOTE 3 - Warning: Causes severe burns.

7.3 Petroleum Spirit, or other solvent completely miscible with petroleum oils.

NOTE 4 - Warning: Combustible. Vapor harmful.

7.4 Primary Standard Water, deionized or distilled, then distilled fresh the same day of use. Store in a glass-stoppered chromic acid-cleaned bottle of borosilicate glass. See Specification D1193.

7.5 Viscosity Oil Standards - Stable petroleum oils selected to cover the desired kinematic viscosity range. They should be transparent and have vapor pressures below 10 mmHg at 40°C. Store away from heat and light in suitable containers, preferably glass.