ASTM D2140 standard test method for carbon-type composition of insulating oils of petroleum origin

6. Apparatus

6.1 No specific apparatus is required for use by this test method. However, to obtain the VGC and ri parameters of Fig. 1, certain measurements of basic physical properties of the test oil must be made. The apparatus required for those measurements is as specified in other ASTM test methods as detailed in Section 7.

7. Procedure

7.1 Obtain a uniform sample of the oil to be analyzed for carbon-type composition, using sampling procedures as specified in Practices D923.

7.2 Determine the viscosity, density and relative density (specific gravity), and refractive index of the sample experimentally by the procedures specified in the following test methods:

7.2.1 Viscosity - See Test Method D445.

7.2.2 Density and Relative Density (Specific Gravity) - See Test Method D1481 or D4052.

7.2.3 Refractive Index - See Test Method D1218.

8. Calculation

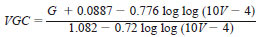

8.1 From the measured viscosity and specific gravity properties of the oil sample (7.2) calculate the viscosity-gravity constant, VGC, as follows (Note 3):

where:

G = relative density (specific gravity) at 15.6°C (60°F), and

V = viscosity, cSt at 37.8°C (100°F).

NOTE 3 - This equation for VGC was devised by Moore and Kaye. Accurate VGC data may be obtained using other equations and other measurement temperatures. Test Method D2501 gives some of these alternatives.

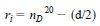

8.2 From the measured density and refractive index properties of the oil sample (7.2) calculate the refractivity intercept, ri, as follows:

where:

nD(20) = refractive index at 20°C (68°F) for D line of sodium, and

d = density at 20°C (68°F).

8.3 Enter the correlation chart, Fig. 1, with the values of VGC and ri, from 8.1 and 8.2. Read from Fig. 1 the corresponding values of % CA, % CN, and % CP.

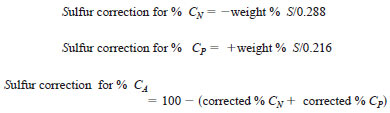

8.4 For oils containing 0.8 % or more sulfur, the accuracy of this test method may be improved by applying a sulfur correction. This may be done by use of the following equations (Note 4):

NOTE 4 - Commercially available oils of the types to which this method applies normally have sulfur contents of less than 0.8 %. Therefore it is unlikely that a sulfur correction will be necessary. For new or experimental oils, or whenever the true sulfur content is unknown, the determination of that quantity is recommended. A satisfactory method is described in Test Method D129.