9. Procedure

9.1 Measure the temperature of the fuel in the container and, if necessary, adjust to 15 to 25°C.

9.2 Shake the fuel container vigorously for 120 +/- 5 s, and then allow to stand on a vibration-free surface for 300 s.

9.3 Place 320 +/- 5 mL of the sample into the fuel reservoir container and check that the temperature is still within the range 15 to 25°C. Record the actual temperature. If any undissolved water is apparent in the fuel at this stage (as determined by Test Method D4176), the test shall be abandoned and the presence of water shall be reported.

9.4 Place the pump suction pipe into the reservoir beaker and run the pump until fuel flows from the fitting to which the filter unit is attached into the collection beaker. Stop the pump and empty any fuel from the collection container back into the reservoir beaker.

9.5 Attach the assembled filter unit to the fitting on the system, re-start the pump, and start the stopwatch.

9.6 After 20 s, record the pressure gage reading. If the pressure gage reading is not within the correct range (7 to 21 kPa), stop the pump and check the apparatus for faults.

NOTE 4 - Test fuels having an extremely high plugging tendency can cause the pressure reading to rise so rapidly that the initial pressure requirement is not met. If this is found to be the case after checking the pump and filter units, the requirement can be ignored and the fact reported in the format given in Section 11.

9.7 Observe the pressure gage reading as pumping continues. When the pressure rises to 105 kPa, stop the pump immediately. If a graduated cylinder was not used for collection, pour the fuel from the collection container into the measuring cylinder. Record the volume collected, rounding off the figure to the nearest 10 mL.

9.8 When 300 mL of sample has been pumped without the pressure reaching 105 kPa, record the maximum pressure reached and discontinue the test at this point.

10. Calculation

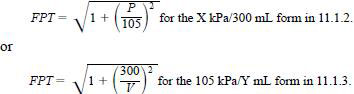

10.1 Calculate and report the normalized filter plugging tendency (FPT) by either of the following equations:

10.2 These two expressions may be normalized in a linear scale through the discontinuity point of 105 kPa/300 mL, giving a single reporting format in terms of an arbitrary unit that is independent of the point of test cessation.