ASTM D1816 Standard Test Method for Dielectric Breakdown Voltage of Insulating Oils of Petroleum Origin Using VDE Electrodes

9. Test Procedure

9.1 Allow the sample and the test cup to equilibrate to ambient temperature. Laboratory and referee tests shall be conducted at room temperature (20 to 30°C).

9.2 To ensure a homogenous sample, gently invert and swirl the sample container several times. Rapid agitation is undesirable, since an excessive amount of air may be introduced into the liquid. Within 1 min after agitation, use a small portion of the sample to rinse the test cell. Drain the rinse. Within 30 s of the rinse, fill the cell slowly with the remaining portion of the sample. The cell is full when closing the cover or baffle allows no air to be in contact with the oil.

9.3 Wait at least 3 min but no more than 5 min between filling the cup and application of voltage for the first breakdown. Apply the voltage increasing from zero at the rate of 0.5 kV/s more or less 5 % until breakdown occurs as indicated by operation of the circuit-interrupting equipment; record the highest rms voltage value that occurred immediately prior to each breakdown. Occasional momentary discharges may occur which do not result in operation of the interrupting equipment; these shall be disregarded until the voltage across the specimen collapses to less than 100 V. Conduct four additional breakdowns waiting at least 60 s but no more than 90 s before applications of voltage for successive breakdowns. (During the intervals before voltage application, between breakdowns, and at the time voltage is being applied, the propeller shall be circulating the oil.)

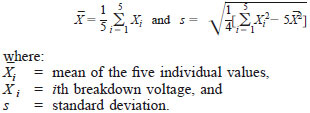

9.4 Calculate the mean and standard deviation of the five breakdowns as follows:

9.5 Using the breakdown voltage values determined in 9.4, determine that the range of the five (5) breakdown voltages does not exceed the values indicated as follows:

1 mm gap setting: Range must be less than 120 % of the mean of the five (5) breakdown voltages

2 mm gap setting: Range must be less than 92 % of the mean of the five (5) breakdown voltages

If this range is exceeded, the tests must be repeated.

9.6 When it is desired merely to determine if the dielectric strength is above or below a specified level, only five breakdowns are required, provided the five values are all above or all below this level. Otherwise, follow the procedure described in 9.4