3. General

3.1 This specification, unless otherwise provided, prescribes the required properties of aviation turbine fuel at the time and place of delivery.

4. Classification

4.1 Three types of aviation turbine fuels are provided, as follows:

4.1.1 Jet A and Jet A-1 - Relatively high flash point distillates of the kerosine type.

4.1.2 Jet B - A relatively wide boiling range volatile distillate.

4.2 Jet A and Jet A-1 represent two grades of kerosine fuel that differ in freezing point. Other grades would be suitably identified.

5. Materials and Manufacture

5.1 Aviation turbine fuel, except as otherwise specified herein, shall consist of refined hydrocarbons derived from conventional sources including crude oil, natural gas liquid condensates, heavy oil, shale oil, and oil sands. The use of jet fuel blends, containing components from other sources are only permitted on a specific, individual basis (see Annex A1).

5.1.1 Fuels used in certified engines and aircraft are ultimately approved by the certifying authority subsequent to formal submission of evidence to the authority as part of the type certification program for that aircraft and engine model. Additives to be used as supplements to an approved fuel must also be similarly approved on an individual basis (see X1.2.4 and X1.11.1).

5.2 Additives - May be added to each type of aviation turbine fuel in the amount and of the composition specified in the following list of approved material:

5.2.1 Antioxidants - In amounts not to exceed 24.0 mg/L active ingredients (not including weight of solvent):

5.2.1.1 2,6-ditertiary-butyl phenol.

5.2.1.2 2,6-ditertiary-butyl-4-methyl phenol.

5.2.1.3 2,4-dimethyl-6-tertiary-butyl phenol.

5.2.1.4 75 % minimum 2,6-ditertiary-butyl phenol, plus 25% max. mixed tertiary and tritertiary-butyl phenols.

5.2.1.5 55 % minimum 2,4-dimethyl-6-tertiary-butyl phenol, plus 15 % minimum 2,6-ditertiary-butyl-4-methyl phenol, remainder as monomethyl and dimethyl tertiary-butyl phenols.

5.2.1.6 72 % minimum 2,4-dimethyl-6–tertiary-butyl phenol, 28% maximum monomethyl and dimethyl-tertiary-butyl phenols.

5.2.2 Metal Deactivator Additive (MDA), in amount not to exceed 2.0 mg/L (not including weight of solvent) on initial fuel manufacture at the refinery. Higher initial concentrations are permitted in circumstances where copper contamination is suspected to occur during distribution. Cumulative concentration of MDA when retreating the fuel shall not exceed 5.7 mg/L.

5.2.2.1 N,N -disalicylidene-1,2-propane diamine.

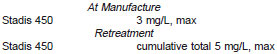

5.2.3 Electrical Conductivity Additive - Stadis 45012 not to exceed 3 mg/L.

5.2.3.1 When loss of fuel conductivity necessitates retreatment with electrical conductivity additive, the following concentration limits apply:

5.2.4 Leak Detection Additive - Tracer A (LDTA-A)13 may be added to the fuel in amounts not to exceed 1 mg/kg.

5.2.5 Other additives are permitted under 5.1 and Section 7.1. These include fuel system icing inhibitor, other antioxidants, inhibitors, and special purpose additives. The quantities and types must be declared by the fuel supplier and agreed to by the purchaser. Only additives approved by the aircraft certifying authority are permitted in the fuel on which an aircraft is operated.

5.2.5.1 Biocidal additives are available for controlled usage. Where such an additive is used in the fuel, the approval status of the additive and associated conditions must be checked for the specific aircraft and engines to be operated.

5.2.5.2 Fuel System Icing Inhibitor:

(1) Diethylene Glycol Monomethyl Ether (DIEGME), conforming to the requirements of Specification D, Type III, may be used in concentrations of 0.10 to 0.15 volume %.

(2) Test Method D 5006 may be used to determine the concentration of IEGME in aviation fuels.