10. Calibration of Apparatus

10.1 Calibrate the apparatus in accordance with 10.2. Recalibrate at regular intervals of not more than seven days or when there has been a change in the apparatus or operator, or when a change of more than 0.7 kPa occurs in the barometric pressure reading.

10.2 Calibrate the apparatus by testing two of the reference fuel blends specified in 7.4, using the procedure specified in Section 11 and, if possible, bracketing the smoke point of the sample. If this is not possible, use the two test blends having their smoke points nearest to the smoke point of the sample.

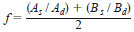

10.2.1 Determine the correction factor f for the apparatus from the equation;

where:

As = the standard smoke point of the first reference fuel blend;

Ad = the smoke point determined for the first reference fuel blend;

Bs = the standard smoke point of the second reference fuel blend;

Bd = the smoke point determined for the second reference fuel blend.

If the smoke point determined for the test fuel exactly matches the smoke point determined for a reference fuel blend, use as the second bracketing reference fuel the reference fuel blend with the next higher smoke point, if there is one. Otherwise, use the one with the next closest smoke point.

10.3 An alternative approach to confirm calibration of the apparatus is for each operator to run a control sample each day the apparatus is in use. Record the results and compare the average from the data base of the control sample using control charts or equivalent statistical techniques. If the difference exceeds the control limits or when new apparatus is used, then the apparatus must be recalibrated.