ASTM D1319 Standard Test Method for Hydrocarbon Types in Liquid Petroleum Products by Fluorescent Indicator Adsorption

10. Procedure

10.1 Ensure that the silica gel is tightly packed in the column and charger section (up to the appropriate level), which includes the appropriate amount of dyed gel (3 to 5 mm) added to an approximately half-full separator section, prior to the start of the sample analysis. See Note 4 for specific guidance.

NOTE 4 - One way to prepare the column for analysis is to freely suspend the column from a loose-fitting clamp placed immediately below the spherical joint of the charger section. While vibrating the column along its entire length, add small increments of silica gel through a glass funnel into the charger section until the separator section is half full. Stop the vibrator and add a 3 to 5-mm layer of dyed gel. Start the vibrator and vibrate the column while adding additional silica gel. Continue to add silica gel until the tightly packed gel extends approximately 75 mm into the charger section. Wipe the length of the column with a damp cloth while vibrating the column. This aids in packing the column by removing static electricity. Vibrate the column after filling is completed for at least 4 min. More than one column can be prepared simultaneously by mounting several on a frame or rack to which an electric vibrator is attached.

10.2 Attach the filled column to the apparatus assembly in the darkened room or area, and when a permanently mounted meter rule is used, fasten the lower end of the column to the fixed rule with a rubber band.

10.3 Chill the sample and a hypodermic syringe to 2 to 4°C. Draw 0.75 more or less 0.03 mL of sample into the syringe and inject the sample approximately 30 mm below the surface of the gel in the charger section.

10.4 Fill the charger section to the spherical joint with isopropyl alcohol. Connect the column to the gas manifold and apply 14 more or less 2 kPa gas pressure for 2.5 more or less 0.5 min to move the liquid front down the column. Increase the pressure to 34 more or less 2 kPa gage for another 2.5 more or less 0.5 min and then adjust the pressure required to give a transit time of about 1 h. Usually a gas pressure of 28 to 69 kPa gage is needed for gasoline-type samples and 69 to 103 kPa gage for jet fuels. The pressure required will depend on the tightness of packing of the gel and the molecular weight of the sample. A transit time of 1 h is optimum; however, high-molecular weight samples may require longer transit times.

10.5 After the red, alcohol-aromatic boundary has advanced approximately 350 mm into the analyzer section, make a set of readings by quickly marking the boundary of each hydrocarbon zone observed in ultraviolet light in the following sequence. (Warning - Direct exposure to ultraviolet light can be harmful, and operators should avoid this as far as possible, particularly with regard to their eyes.) For the noninfluorescent saturate zone, mark the front of the charge and the point where the yellow fluorescence first reaches its maximum intensity; for the upper end of the second, or olefin zone, mark the point where the first intense blue fluorescence occurs; finally, for the upper end of the third, or aromatic zone, mark the upper end of the first reddish or brown zone. Refer to Fig. 2 as an aid in identifying the boundaries. With colorless distillates, the alcohol-aromatic boundary is clearly defined by a red ring of dye. However, impurities in cracked fuels often obscure this red ring and give a brown coloration, which varies in length, but which shall be counted as a part of the aromatic zone, except that when no blue fluorescence is present, the brown or reddish ring shall be considered as part of the next distinguishable zone below it in the column. With some oxygenate blended fuel samples, another red band may appear several centimetres above the reddish or brown alcohol-aromatic boundary (see Fig. 3) and should be ignored. Avoid touching the column with the hands while marking the zones. If the boundaries have been marked off with index clips, record the measurements.

10.6 When the sample has advanced at least another 50 mm down the column, make a second set of readings by marking the zones in the reverse order as described in 10.5 so as to minimize errors due to the advancement of boundary positions during readings. If the marking has been made with a glass-writing pencil, two colors can be used to mark off each set of measurements and the distances measured at the end of the test with the analyzer section lying horizontally on the bench top. If the boundaries have been marked off with index clips, record the measurements.

10.7 Erroneous results can be caused by improper packing of the gel or incomplete elution of hydrocarbons by the alcohol. With precision bore columns, incomplete elution can be detected from the total length of the several zones, which must be at least 500 mm for a satisfactory analysis. With standard wall tubing, this criterion of total sample length is not strictly applicable because the inside diameter of the analyzer section is not the same in all columns.

NOTE 5 - For samples containing substantial amounts of material boiling above 204°C, the use of isoamyl alcohol instead of isopropyl alcohol may improve elution.

10.8 Release the gas pressure and disconnect the column. To remove used gel from the precision bore column, invert it above a sink and insert through the wide end a long piece of No. 19-gage hypodermic tubing with a 45° angle tip. By means of 6-mm outside diameter copper tubing at the opposite end for attaching a rubber tube, connect to a water tap and flush with a rapid stream of water. Rinse with residue-free acetone and dry by evacuation.

11. Calculation

11.1 For each set of observations calculate the hydrocarbon types to the nearest 0.1 volume % as follows:

Aromatics, % volume = (La/L) x 100

Olefins, % volume = (Lo/L) x 100

Saturates, % volume = (Ls/L) x 100

where:

La = length of the aromatic zone, mm,

Lo = length of the olefin zone, mm,

Ls = length of the saturate zone, mm, and

L = sum of La + Lo + Ls.

Average the respective calculated values for each type and report as directed in 12.1. If necessary, adjust the result for the largest component so that the sum of the components is 100 %.

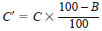

11.2 Eq 1, Eq 2, and Eq 3 calculate concentrations on an oxygenate-free basis and are correct only for samples that are composed exclusively of hydrocarbons. For samples that contain oxygenated blending components (see 1.5), the above results can be corrected to a total sample basis as follows:

where:

C' = concentration of hydrocarbon type (% volume) on a total sample basis,

C = concentration of hydrocarbon type (% volume) on an oxygenate-free basis, and

B = concentration of total oxygenate blending components (% volume) in sample as determined by Test Methods D4815 or D5599 or equivalent.