ASTM D1123 standard test methods for water in engine coolant concentrate by the Karl Fischer reagent method

TEST METHOD B - COULOMETRIC TITRATION

14. Apparatus

14.1 Coulometric Titrator - A complete control unit with titration chamber and clamp, platinum sensing electrodes, generator, magnetic stirrer, and meeting requirements 14.2 and 18.1.

14.2 The instrument used for determining water in liquids is designed and calibrated to deliver a known number of milliamperes of current which generates sufficient iodine to neutralize a known number of micrograms of water per minute.

14.3 In order to determine the water content of engine coolants, this method requires a two-part titration solution that is brought to zero dryness by iodine produced by the generator when the instrument is powered up. The sample is added and the water content is read directly in micrograms.

14.4 Glass Syringe, 50-mL, for removing excess solution from the titration chamber.

14.5 Syringe, 25-µL, fitted with a 11.5-cm hypodermic needle for introduction of samples into the titration chamber.

14.6 Syringe, 1-µL, fitted with a 11.5-cm hypodermic needle for standardization of instrument.

14.7 Fluorocarbon Sealing Grease, 15 to seal the titration chamber against atmospheric moisture.

14.8 Septums, to seal sample port but allow introduction of samples by a needle with a minimum of moisture contamination. Septum caps should be replaced as required to prevent air leakage as indicated by instrument drift.

15. Reagents

15.1 Generator Solution - (Warning - see 16.1) - Provides iodine in the reaction mixture.

15.2 Titration Solutions, supplied in two parts, Part A and Part B. The two parts are mixed prior to adding to the titration chamber.

15.3 Neutralizing Solution - Methanol - (Warning - see 16.2) - Anhydrous, high purity methanol containing approximately 20 mg H2O/mL.

16. Hazards

16.1 Generator Solution - Refer to the manufacturer's material safety data sheet for precautions and hazards.

16.2 Methanol - Poison; flammable; may be fatal or cause blindness if swallowed; cannot be made non-poisonous; harmful if inhaled.

17. Preparation of Apparatus

17.1 Clean, thoroughly dry, and assemble the titration chamber using sealing grease. Connect the titration chamber to the titrator.

17.2 Pour Part B of the titration solution into Part A, close, thoroughly mix by shaking, and allow to cool to room temperature.

17.3 Remove the septum from the sample port and pour the mixture of Parts A and B, made in 17.2, through a dry funnel into the titration chamber. Immediately replace the septum cap.

17.4 Add approximately 6 mL of the generator solution into the generator cartridge. The surface of the generator solution should be below the level of the surface of the titrating solution to prevent backflow contamination of the titrating solution.

17.5 Attach the 11.5-cm hypodermic needle to a 20-mL syringe. Withdraw about 15 mL of neutralizing solution. Insert the needle through the sample port septum and lower it until the tip of the needle is below the surface of the titration solution.

17.6 Slowly inject the neutralizing reagent into the titration solution until it changes color from brown to red. This indicates the end point is near. Continue the addition very slowly. The total volume required will range between 5 and 15 mL depending on the residual moisture in the system.

17.7 All liquid samples to be tested should be at room temperature for analyses.

18. Verification of System by Direct Titration of Water

18.1 To determine if the titration system is functioning properly, fill a 1-µL syringe with distilled water to the 1-µL mark. Weigh the filled syringe. Insert the needle through the sample port septum and lower it until the tip of the needle is below the surface of the titrating solution. Depress the START key and immediately inject the water into the titration solution. Remove the syringe and reweigh. The titration is complete when the result is displayed with the symbol "mcg". The weight of the water injected in micrograms should approximate the instrument reading.

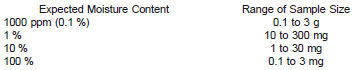

19. Sample Sizes

19.1 The sample size is governed by the expected range of moisture content:

20. Procedure

20.1 Using an appropriate dry syringe and needle (see 19.1), draw the sample liquid to be tested into the syringe and discharge the contents into a waste container. Withdraw the sample into the syringe until above the desired calibration mark. Remove the needle from the sample container and force the extra liquid from the syringe to exactly the calibration mark. Wipe the tip of the needle with a clean tissue or towel.

NOTE 4 - For most determinations, the volumetric addition of the sample is adequate. However, better accuracy may be obtained by weighing the syringe before and after the addition of the sample.

20.2 The instrument should be left on stand-by when not in use. If the instrument is turned off, it is necessary to allow the titration solution to stabilize or to replace the solution.

21. Calculation

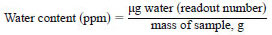

21.1 Calculate the amount of water present in the sample as follows:

(The instrument can perform this computation automatically. Consult the operating instructions.)

22. Precision and Bias

22.1 Precision:

22.1.1 Repeatability - Duplicate results by the same operator should not differ by more than 3 ppm, 95 % of the time.

22.1.2 Reproducibility - The results submitted by one laboratory should not differ from that of another laboratory by more than 10 ppm, 95 % of the time.

22.2 Bias - Since there is no accepted reference material for the procedure in this test method, bias has not been determined.

23. Keywords

23.1 engine coolants; Karl Fischer; water content