11. Procedure

11.1 Pipet 10 mL of a thoroughly mixed sample into a 250 mL tall-form spout-less beaker. Allow 1 minute drain time. Add about 90 mL of distilled water (Note 2).

NOTE 1 - The amount of water added is not critical; however, it must be sufficient to cover the electrode tips. If the reserve alkalinity is less than 2, the sample size may be increased to 50 mL diluted to 100 mL with water, and the total titration divided by 5 to give the reserve alkalinity as defined.

11.2 Prepare the calomel and glass electrode as described in Section 9. Place the beaker containing the test solution on the titration stand, adjust so that the lower half of each electrode is immersed, start the stirrer, and adjust the rate of the stirring so that there is vigorous stirring without spattering. Fill the 50-mL buret with standardized 0.100 N HCl. The normality of the acid used may be in the range from 0.095 to 0.105, but the actual titration will require correction to give the equivalent titration with 0.100 N acid. Position the buret tip inside the beaker. Adjust the pH meter temperature compensator to agree with the solution temperature. Record the initial pH and proceed with the titration to a pH of about 7. Use a slow, drop wise titration rate from pH 7 to approach the end point of pH 5.5. Record the volume of acid used, acid normality, and sample size. Switch the pH meter to standby and rinse the electrodes with water and dry with clean absorbent material before the next determination. When the pH meter is not in use, immerse the electrodes in distilled water. When a large number of reserve alkalinity determinations are made during a period of several hours, it is recommended that the meter be recalibrated at various intervals as described in 10.1.

NOTE 2 - In the event that the glass electrode becomes coated with an oil, grease, or other film, it is recommended that a 1 to 1 solvent mix of toluene and ethyl acetate be used to remove the film.

12. Calculations Using Reserve Alkalinity Data

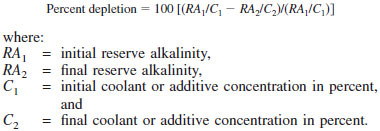

12.1 Calculations of percent depletion during simulated or actual coolant service may be obtained by use of the following equation:

NOTE 3 - In the case of a coolant solution, if the concentration is unknown, it can be determined by appropriate test methods, such as refractive index, freezing point, or specific gravity, and by reference to available tables. The water content of the coolant solution can be determined by Test Method D1123, and the concentration calculated.

12.2 The percent depletion data allows coolant investigators to compare, on an equivalent basis, the reserve alkalinity data from a number of identical tests on similar coolants.

12.3 In the case of vehicle service tests the percent depletion should be reported on the basis of some unit of mileage, such as 10,000 miles. As implied in 5.2, percent depletion of the reserve alkalinity, although related to coolant durability and the condition or performance of cooling system, is only a part of the coolant evaluation procedure.